Common faults of tension controller

- The tension controller ammeter does not display, unable to control the discharge tension. Reasons and solutions:

(1) The input voltage of the magnetic powder brake is abnormal. Analyze the cause of abnormal power supply and carefully check to ensure that the input voltage is normal.

(2) The copper winding of the magnetic powder brake was short circuited and burned out. Rewind the winding and make a record, or replace the winding with a new one.

(3) The solder joint of the copper winding of the magnetic powder brake has come loose, making it impossible to form a closed circuit with the circuit. Just re weld it.

- The current meter indicator of the tension controller has an indication, but it is unstable at different times. Reasons and solutions:

(1) The copper winding joint of the magnetic powder brake has fallen off or has poor contact due to tin soldering. Re weld firmly.

(2) The magnetic powder in the magnetic powder brake missed the printing of variable data and did not reach the specified value. Supplement magnetic powder to standard quantity

(3) The reason for the needle itself or the malfunction of the adjuster. Replace the ammeter or recalibrate it, check the relevant internal components, and replace the positioner.

Automatic tension controller malfunction

reason

- It is highly likely that the detection roller is not round, the bearing is damaged, or the detection roller is bent;

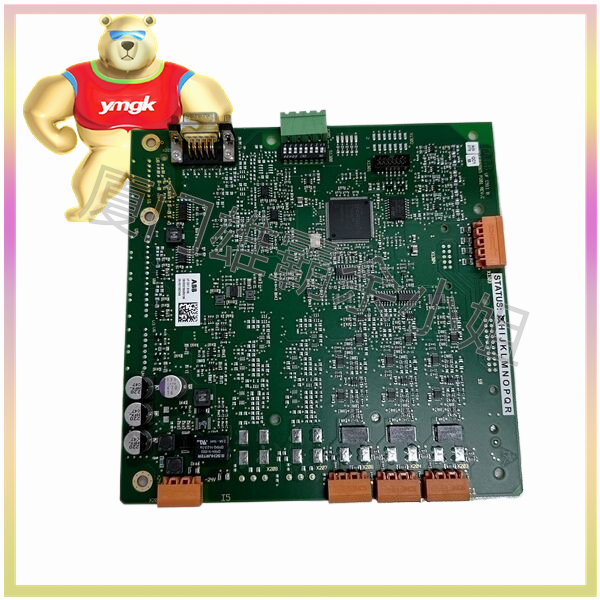

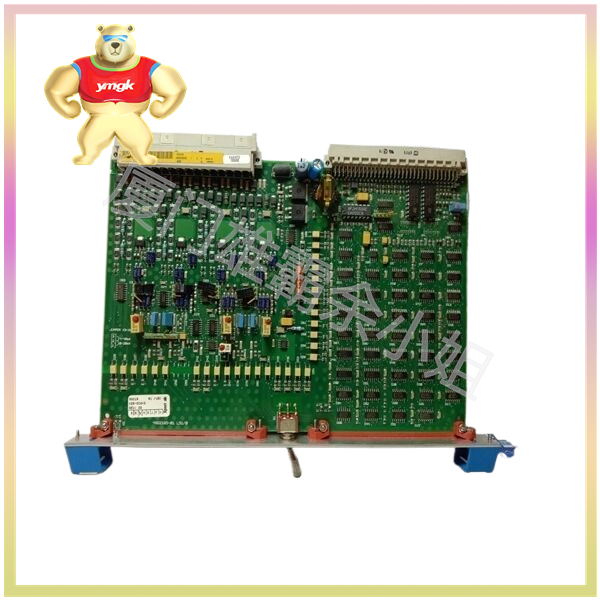

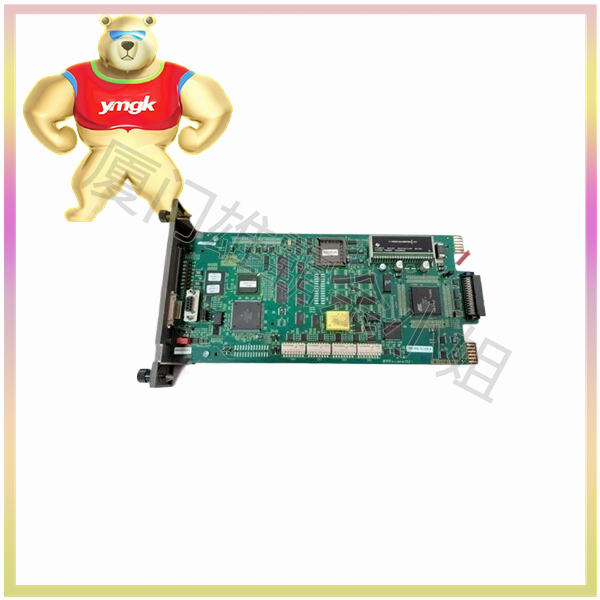

- There are issues with the magnetic powder brake, clutch, and driver components;

- Sensor signal malfunction or calibration error.

resolvent

- Reinstall the mechanical installation;

- Replace with a suitable actuator;

- Select the cooperative sensor and recalibrate it correctly.