PLCs use different types of modules to interact with various devices and perform specific tasks. The types of modules used in PLC systems may vary depending on the manufacturer and specific application, but the following are some typical types:

output module

Analog input module

Analog Output Module (AOM)

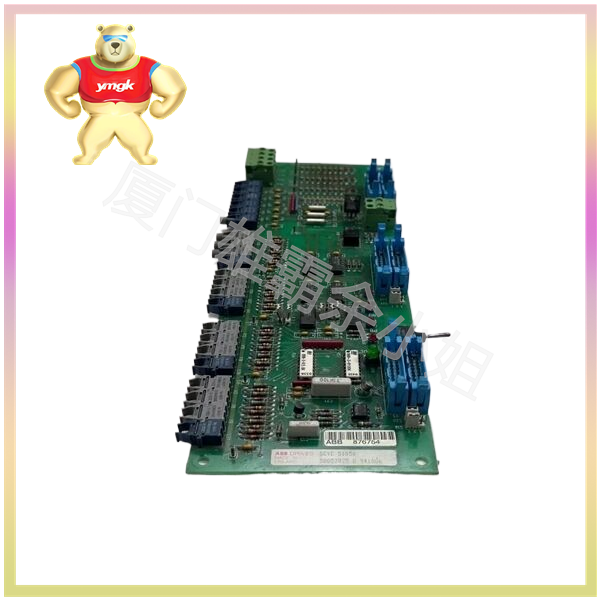

communication module

Professional modules

Positioning module

Temperature control module

Security module

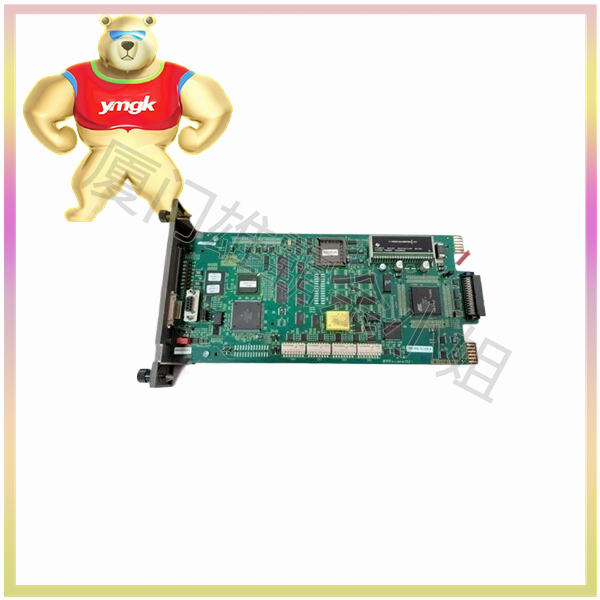

PLC CPU (Central Processing Unit) module

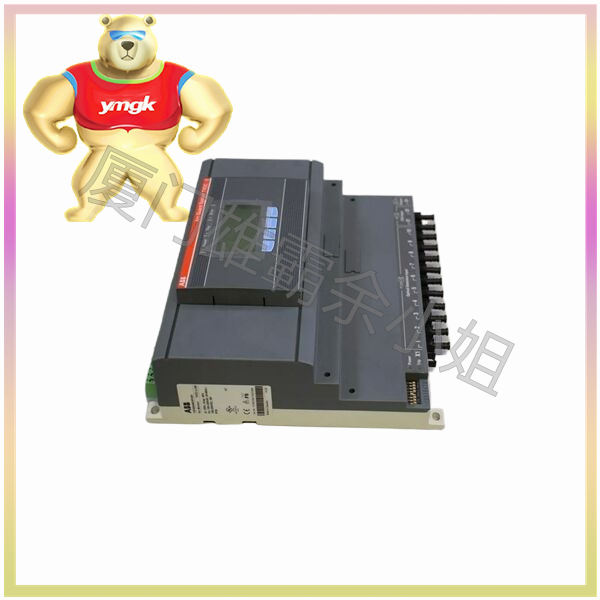

Power module

Remote input/output module

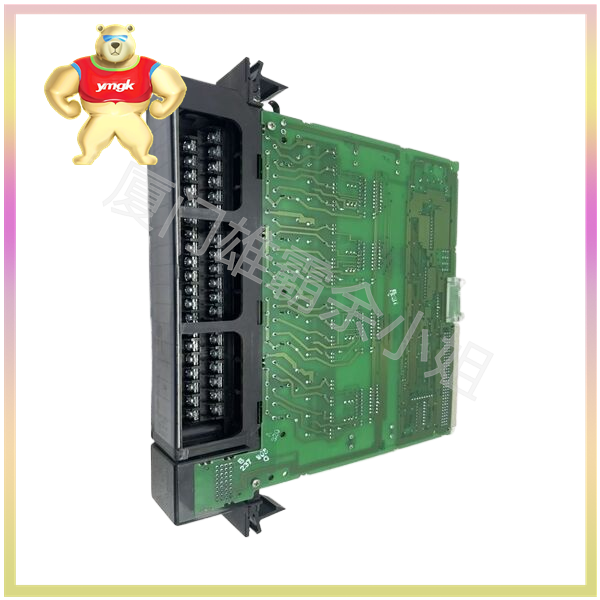

Input module

The input module connects the PLC to external devices such as sensors, switches, and other input devices. These modules receive external device signals and convert them into structures that PLC can understand.

output module

The output module connects the PLC to external devices such as motors, solenoids, and other output devices. They receive PLC signals and convert them into a format that can operate external devices.

Analog input module

The analog input module is used to process analog signals from temperature sensors, pressure sensors, and potentiometers. These modules convert continuous analog signals into digital values that can be processed by PLC.

Analog Output Module (AOM)

The analog output module generates analog control signals for controlling devices such as variable speed drives (or proportional control valves). They convert PLC digital signals into analog output signals.

communication module

The communication module allows PLC to communicate with other devices (or) systems, such as human-machine interface (HMI), remote I/O devices (or) other PLCs. These modules can support various communication protocols, such as Ethernet, Profibus, Modbus, etc.

Professional modules

Some PLC systems include specialized modules for specific operations, such as high-speed counting, motion control, and/or safety functions, such as emergency stop and safety relay modules.

Positioning module

These modules are used for motion control and positioning applications. They can control servo systems, stepper motors, and other positioning devices.

Temperature control module

The temperature control module is used in applications that require precise temperature control, such as industrial ovens or furnaces. They can communicate with temperature sensors to regulate heaters or coolers.

Security module

The safety module aims to ensure the safe operation of machines and processes. To achieve safety functions, they may include safety relays, emergency stop modules, and safety input/output modules.

PLC CPU (Central Processing Unit) module

The CPU module is the brain of a PLC, containing the processor, memory, and other components required to run PLC programs and manage the system.

Power module

The power module provides the power required by the PLC and its related modules. They ensure the smooth and reliable operation of the PLC system.

Remote input/output module

These modules enable the PLC system to be extended by connecting remote input and output devices that are far away from the main PLC unit.

These are the most popular modules in PLC systems. The specific modules used in PLC systems are determined by application requirements and the products of the PLC manufacturer.