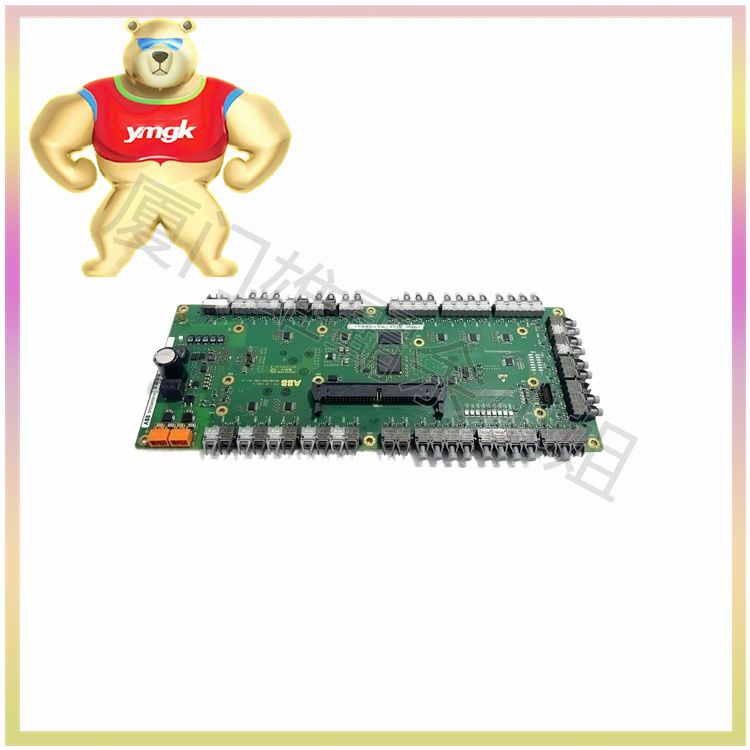

The PLC control system can be composed of integral PLC or modular PLC. The I/O and CPU of the integrated PLC are on the same printed circuit board, with a compact structure, small size, and low price. Most small programmable controller control systems use integral programmable controllers. Modular PLC control systems can easily expand functions, increase or decrease the number of I/O points, facilitate maintenance and replacement, and quickly identify and handle faults. Therefore, control systems with high functional requirements usually use modular PLC, which is currently the most widely used PLC control system.

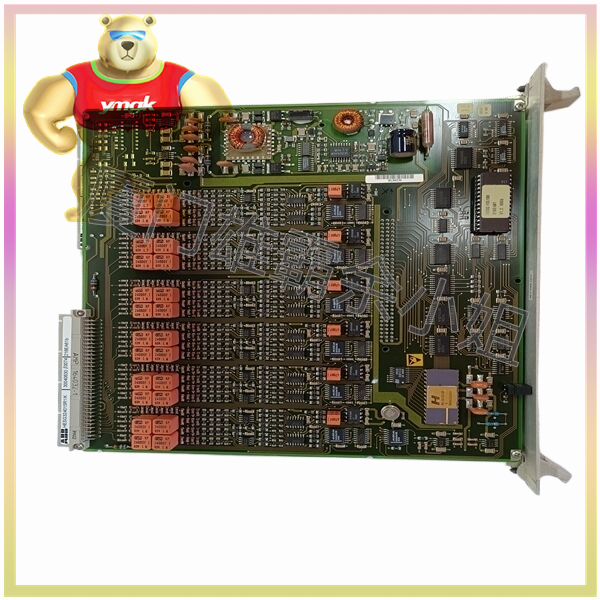

User memory for programmable controller control system

Usually, PLC control systems use CMOS RAM as user memory, which has the characteristic of low static current consumption (1/A). In order to maintain user programs and on-site data during power outages, PLCs typically use lithium batteries as a backup power source.

If the process requirements of the controlled system are fixed and the program developed by the PLC is complete and does not require modification, EPROM (optional part) can be used to solidify the user program to avoid technical confidentiality or human modification of the PLC program.

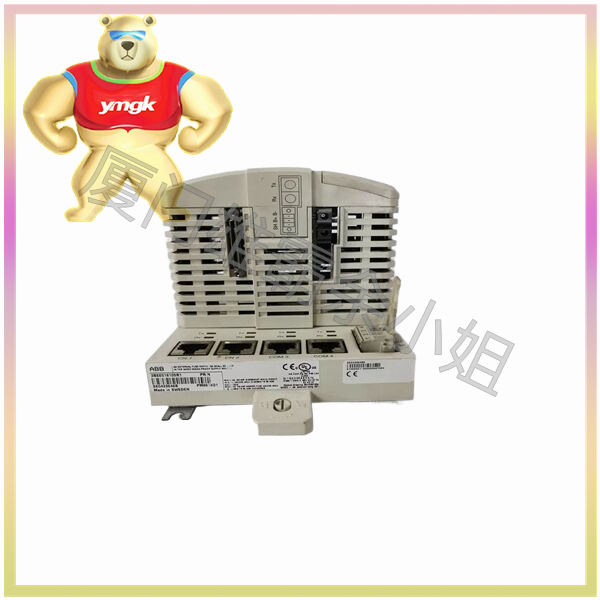

Communication networking function of programmable controller control system

Small PLC automatic control systems are mostly single machine active and can meet functional requirements, but the communication interface of the upper computer cannot be used.

If users need to integrate the PLC automatic control system into the factory’s active control network, they should choose a PLC automatic control system with a communication interface. Both large and medium-sized PLC automatic control systems generally have communication functions.

At present, some high-performance small computers also have communication interfaces. The PLC control system is connected to the upper computer or another PLC automatic control system through an RS-232 serial interface, and can also be connected to external devices such as printers.

Introduced the knowledge of the programmable controller structure, programmable controller memory, and programmable controller communication interface of the programmable controller control system. In practical use of PLC, various factors should be summarized and considered according to the user’s needs, and cost-effective products should be selected to fully meet the control requirements of the controlled object and fully utilize the functions of the PLC automatic control system.