The main reasons for the aging of PLC controller equipment are as follows:

(1) Long term use: During prolonged use, various components of PLC equipment will gradually wear and age. This is a natural law that is difficult for any electronic device to avoid. Long term operation can lead to a decrease in component performance, which in turn can cause device aging.

(2) Environmental factors: The working environment of PLC controllers has a significant impact on their performance and service life. If the equipment is exposed to harsh environments such as high temperature, high humidity, and high dust for a long time, its internal electronic components and circuits are easily damaged, leading to accelerated aging of the equipment.

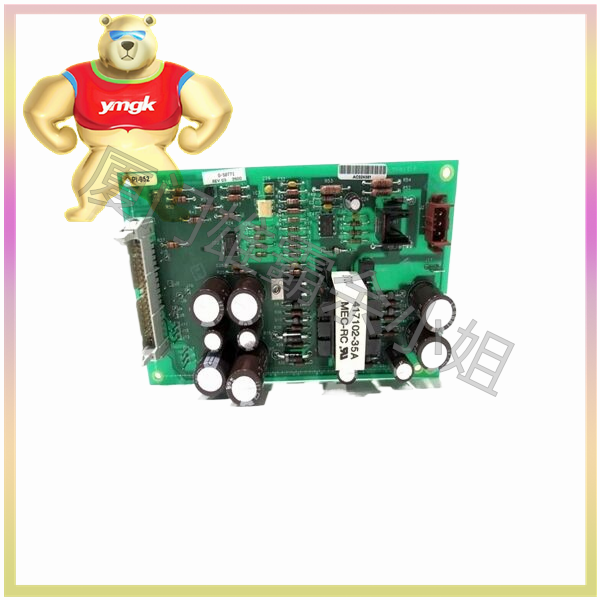

(3) Quality of power supply: The quality of power supply directly affects the reliability of PLC use. Frequent voltage fluctuations can accelerate the aging of electronic components in voltage modules. For PLC systems that have been used for many years, if program execution errors often occur, the quality of the voltage module power supply should be considered first.

(4) Improper maintenance and upkeep: PLC controllers require regular maintenance and upkeep, including cleaning, tightening loose parts, replacing aging components, etc. If not maintained properly or in a timely manner, it can lead to a decrease in equipment performance and accelerate aging.

In order to extend the service life of PLC controllers, a series of measures need to be taken, including selecting high-quality PLC equipment, improving the working environment, optimizing the quality of power supply, and strengthening maintenance and upkeep. At the same time, regular inspection and testing of PLC equipment to promptly identify and address potential issues is also an important means of preventing equipment aging.