Fundamentals of Motion Systems and Robots

A motion control system is a simple concept: initiating and controlling the movement of a load to perform a task. They have precise speed, position, and torque control capabilities. Examples of using motion control include product positioning required by applications, synchronization of independent elements, or rapid start and stop of motion.

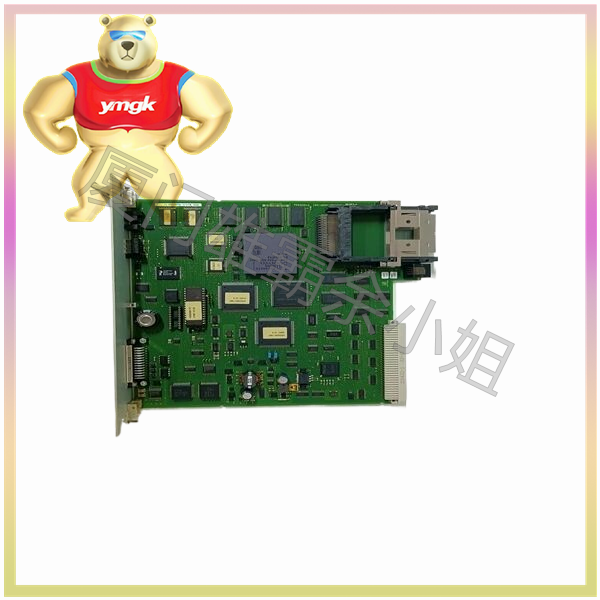

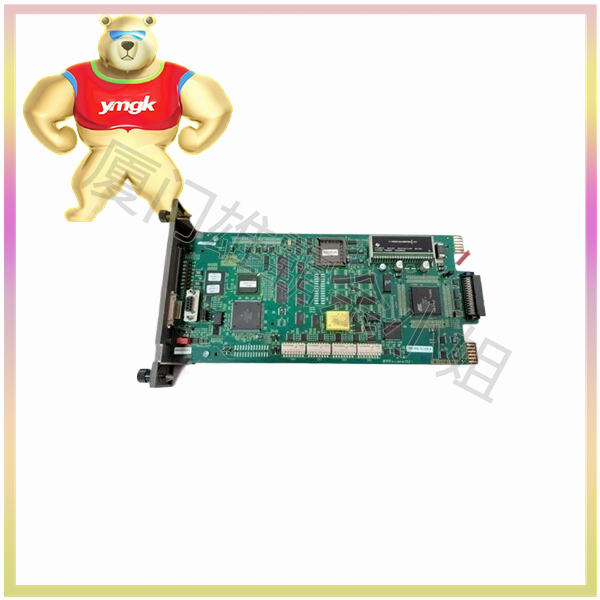

These systems typically consist of three basic components: controllers, drivers (or amplifiers), and motors. The controller plans the path or trajectory calculation, sends low voltage command signals to the drive, and applies necessary voltage and current to the motor to generate the required motion.

Programmable logic controllers (PLCs) provide an inexpensive and noise free motion control method. Cascade logic programming has always been the main content of PLCs, and new models are represented by human-machine interface (HMI) panels, which are visual representations of programming code. PLCs can be used to control various action control devices and mechanical logic control.

In a traditional PLC based motion control system, high-speed pulse output cards are applied to PLCs to generate pulse sequences for each servo or stepper drive. The driver receives pulses, and each pulse has a pre-set quantity. A separate signal is used to determine the direction of transmission. This method is called ‘steps and directions’.

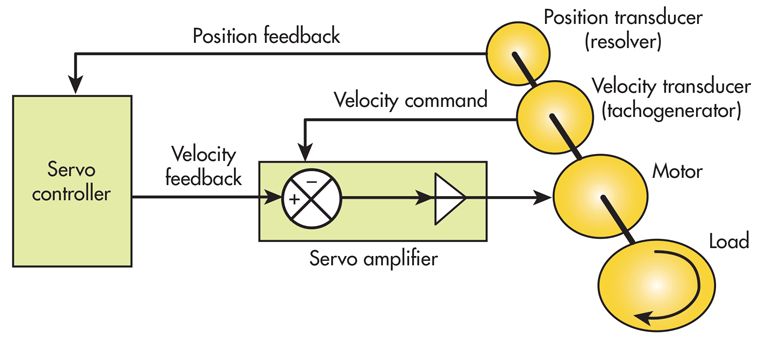

This diagram depicts a traditional motion control system, including a servo controller, motor, and sensors.

The commonly used terms in motion control vocabulary include:

·Speed: the rate of change in position related to time; A vector composed of size and direction.

·Speed: The magnitude of speed.

·Acceleration/Deceleration: The rate of change of speed over time.

·Load: The driving component of the servo system. This includes all components of the machine and the moving work.

·Servo amplifier: The device controls the power of the servo motor.

·Servo controller: also known as position controller, this device provides programming or instructions for servo amplifiers, usually in the form of analog DC voltage signals.

·Servo motor: a device for moving loads. This is the main moving component, which may include a series of primary drivers such as actuators and induction motors.

·Stepper controller: a device that provides pulses to stimulate the windings of a stepper motor and generate mechanical rotation. It is also known as a speed controller. The frequency or pulse determines the speed of the motor, and the number of pulses determines the position of the motor.

·Parser: a device that monitors the position of servo motors and loads. Also known as a position sensor.

·Speed sensor: also known as a speed generator, it monitors the speed of the servo monitor.

Baxter, which is rethinking robot technology, is a perfect example of ready-made collaborative robot solutions.

According to the American Institute of Robotics, “A robot is a reprogrammable, multifunctional robotic arm that can move objects, parts, tools, or special equipment through various actions

Although some components found in motion control systems are found inside robots, they are fixed inside the robot. The speed, execution force, and mechanical connections of the motor are all components of the robot. The components that make up a robot system are similar to motion control systems. This is a controller that allows parts of the robot to work together and connect to other systems. The program code is installed into the controller. In addition, many modern robots use HMIs based on computer operating systems (such as Windows PC).

The robot itself can be an articulated robot arm, Cartesian, cylindrical, spherical, Scala, or a parallel selection robot. These are considered the most typical industrial robots. For a complete list of robots, refer to our “Differences between Industrial Robots”. The robot system also has a driver (i.e. engine or motor) to move the connecting rod to a designated position. Connection is the part between joints. Robots use hydraulic, electric, or pneumatic drives to achieve motion. Sensors are used for feedback in robot environments, providing visual and auditory support for operational control and safety. They collect information and send it to the robot controller.

Sensors can enable robots to work collaboratively – resistance or touch feedback allows robots to operate around human workers. The end effector is connected to the arm and function of the robot; They have direct contact with the manipulated products. Examples of end effectors include clamps, suction cups, magnets, and welding torches. The main difference between a motion system and a robot is time and money. Modern robots are promoted as ready-made turnkey solutions.

For example, a robotic arm is already constructed and easy to install. Universal robots provide common examples of “devices” and “robots”. They can be programmed through the HMI control panel and can also record movement actions by recording position movements. The end effector can be replaced according to your needs, and engineers don’t have to worry about individual programming of robot moving parts.

Universal robots provide simple location recording programming to assist end-users. The final effector can exchange specific applications. The disadvantage of robots is cost. On the other hand, the components that make up the motion control application are modular, and modular control of the motion system provides greater cost control.

However, for users, there is a greater knowledge requirement to operate the motion control system correctly. Its components require separate programming from the end user. If engineers need multiple settings, module configurations, availability, and cost constraints, then an action control system can provide the benefits that engineers are seeking. An experienced engineer can spend time planning, installing, and debugging an action control system. You can mix and match old and new hardware, and create solutions for the system.

Rockwell Automation’s FactoryTalk is a modern software controller that can run simultaneously in motion control and robot systems. The next major difference between these two systems is software. In the past, hardware drove purchasing decisions, but now there are slight differences in product hardware. Action control systems that rely heavily on hardware, especially legacy systems, require more maintenance to ensure proper operation.

Closed systems or modern plug-in components rely more on software operation. The functionality of software is crucial because many users expect modern controllers to be able to complete all necessary tasks. This means that money will be spent on individual components, while more money will be spent on monitoring operations such as PCs and advanced HMIs. Users also hope that the software controller is easy to use. The simpler the interface and operation controller, the more likely users are to choose its application.

This saves time and money on training and setup. Modern controllers that can be used on motion systems and robots have software options that can provide several automated processes.