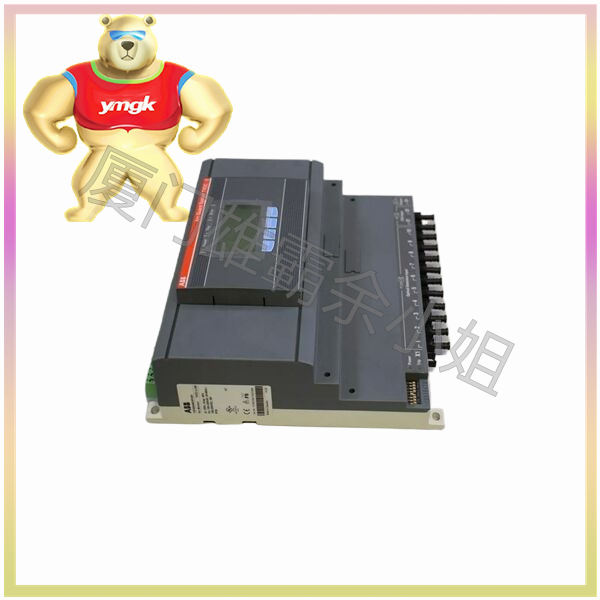

PLC input/output (I/O) refers to the circuit used by a PLC system to connect input and output devices. Input refers to the signals received by the PLC, such as state changes or signals detected by sensors or switches, while output refers to the signals output by the PLC to the devices it controls, such as control signals for motors or relays. Usually, the I/O module of a PLC has multiple channels that can connect multiple input or output devices simultaneously. This allows PLC to control multiple devices and receive multiple input signals simultaneously. I/O modules are usually programmable, which means they can be configured in PLC programs to provide the required inputs and outputs.

The input and output terminal design of PLC (Programmable Logic Controller) adopts technologies such as circuit isolation and signal conversion, which can achieve precise control of various field devices. The principle is as follows:

- Input port principle:

When a sensor or switch is triggered, it will output an electrical signal. The input port of the PLC isolates the signal and converts it into a digital signal, which is then transmitted to the CPU through an internal circuit.

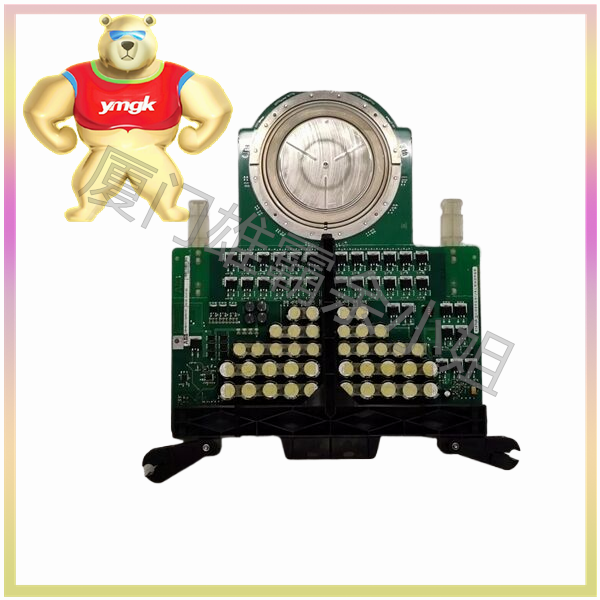

- Principle of output port:

The output port of PLC converts digital signals into electrical signals. The electrical signal drives a relay or another output device in the output port, thereby controlling the on-site equipment.

In short, the PLC input port inputs the electrical signals of the on-site equipment into the digital circuit of the control system, performs logical operations and judgments, sends the judgment results to the output port, and then converts them into electrical signals to output to the actual equipment for control and operation.

The input and output signals of PLC are mainly divided into three types:

- Digital signal: Digital signals are binary signals with only two states, namely “1” and “0”. PLC collects and outputs digital signals through digital input and output modules.

- Analog signal: An analog signal is a continuously changing signal that can take any value. Physical quantities such as temperature, pressure, and flow rate are analog signals. PLC needs to collect and output analog signals through analog input/output modules.

- Special signals: Special signals refer to other types of signals besides digital and analog signals, such as encoder signals, pulse signals, communication signals, etc. PLC can collect and output special signals through special modules.

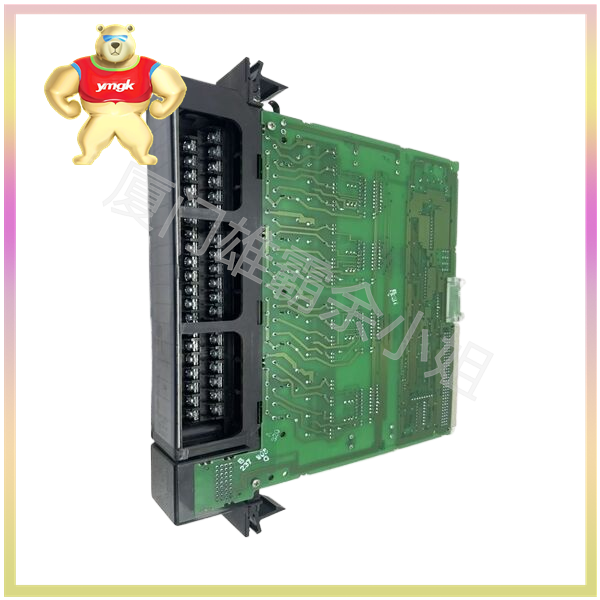

The wiring method of PLC input and output terminals depends on the PLC model and application scenario. Generally speaking, there are several common input methods for PLC, including:

- DC input: Usually uses 2 or 3 wires for input. The 2-wire input needs to be connected to the negative terminal of the power supply and the input terminal, while the 3-wire input needs to be connected to the positive and negative terminals of the power supply and the input terminal.

- AC input: The input terminal usually has two wires, so it is important to ensure that the input voltage is consistent with the rated input voltage of the PLC.

- Optocoupler input: The input terminal is a optocoupler that can use external voltage as the input signal, ensuring safety and reliability.

There are also various types of PLC outputs:

- DC output: There are generally two types of relays: solid-state relays and mechanical relays, and there are also different options for output voltage.

- AC output: Similar to AC input, the output signal needs to closely match the device parameters.

- Relay output: A common way to connect external devices to PLCs, which requires determining whether the power supply and current match.

- Analog output: Proportional signals that output digital signals, commonly available in two types: 0-10V and 4-20mA.

In short, ensuring the safety, matching, grounding, and correct circuit wiring of input and output ports is the key to the operation of PLC. In practical applications, parameter settings and connection methods are generally determined based on equipment requirements and PLC manuals or installation instructions.