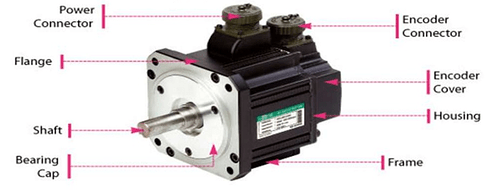

As the core of industrial automation systems, industrial controllers have the following significant characteristics:

Reliability and Stability: Industrial controllers are designed to operate stably in harsh industrial environments, with strong anti-interference capabilities and reliability.

Real time capability: able to respond in real-time to changes in input signals, quickly make control decisions, and ensure the continuity and synchronization of production.

Flexibility and programmability: Users can write and modify control programs as needed to adapt to different industrial applications.

Rich interfaces: With multiple communication interfaces and protocols, it facilitates data exchange and communication with other devices and systems.

Easy to maintain and expand: adopting modular design, convenient for maintenance and functional expansion.

High control accuracy: By adopting advanced control algorithms and hardware design, high-precision control of the production process is achieved.

Intelligence and Networking: With the development of IoT and artificial intelligence technologies, industrial controllers are gradually moving towards intelligence and networking, enabling remote monitoring, fault diagnosis, and automatic optimization functions.

4、 Summary

As the core component of industrial automation systems, industrial controllers come in a wide variety of types and have powerful functions. Different types of industrial controllers have their own characteristics and are suitable for different industrial application scenarios. With the continuous development of technology, industrial controllers will continue to move towards intelligence and networking, injecting new vitality into the development of industrial automation systems. In the future, industrial controllers will play a more important role in improving production efficiency, reducing costs, and ensuring product quality.