Working principle of automatic control system servo system

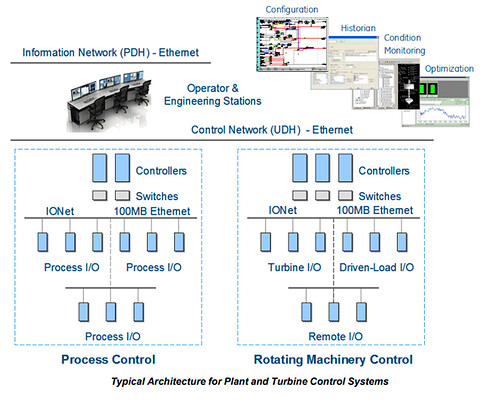

A servo system, also known as an automatic control system, is a feedback control system that accurately follows or reproduces a process. It is an automatic control system where the output controlled variables such as object position and state can follow any changes in the input target or given value.

The task of the servo system is to amplify, transform, and regulate the power according to the requirements of the control command, so that the torque, speed, and position control output by the driving device can be flexibly applied.

The main functions of a servo system are:

- Send low-power command signals to control high-power load devices

- It can achieve original torque synchronous transmission without mechanical connection

- The output mechanical displacement can accurately track electrical signals

Classification of servo systems:

- Classified by system components into electrical servo system, hydraulic servo system, electrical hydraulic servo system, and electrical electrical servo system, etc

- Classify according to the physical properties of the system output into speed or acceleration servo systems, position servo systems, etc

- Classified into analog servo systems and digital servo systems based on the characteristics of system components and signal effects

- According to the structural characteristics of the system, it can be classified into single loop servo system, multi loop servo system, open-loop servo system, and closed-loop servo system

- According to the driving components of the servo system, it can be classified into stepper servo system, DC motor servo system, and AC motor servo system

The servo system mainly consists of a controller, servo drivers, feedback devices, various sensors, relays, and servo motors.

The control methods of servo systems include speed control, torque control, and position control. The first two are controlled by analog signals, while the latter are controlled by pulses.