working principle

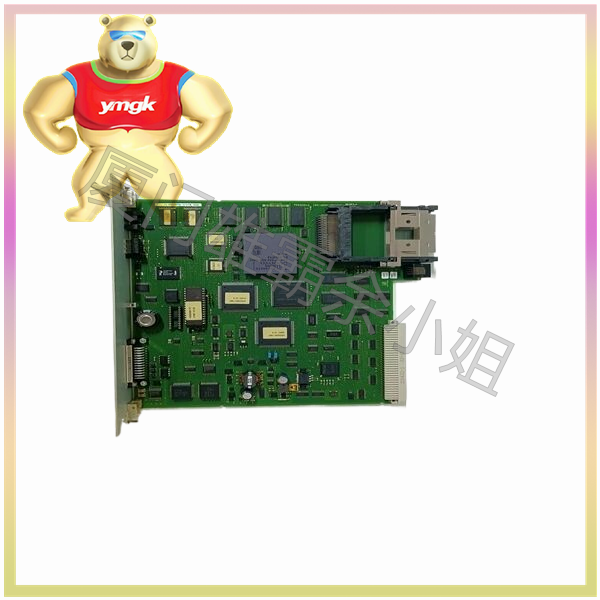

Currently, mainstream servo drives use digital signal processors (DSPs) as the control core,

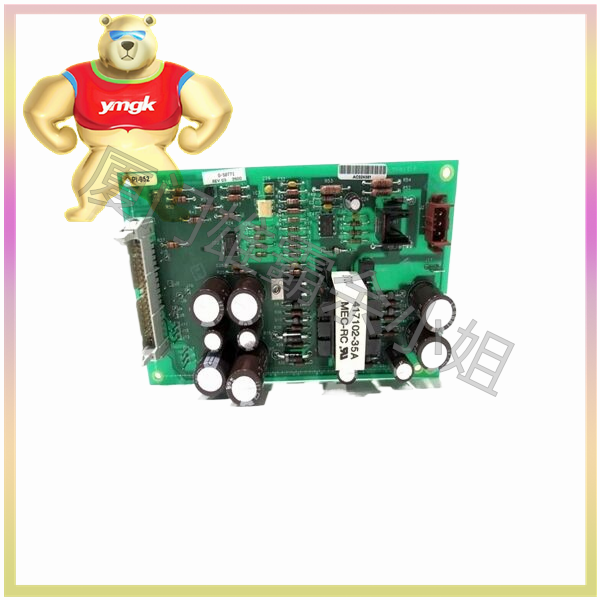

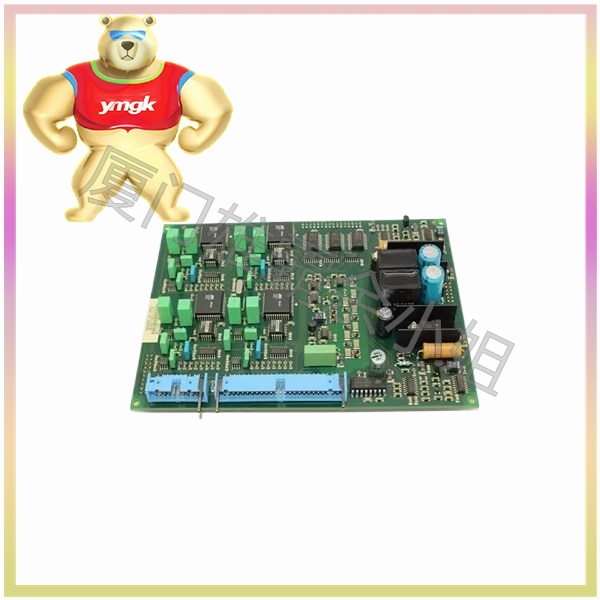

Complex control algorithms can be implemented to achieve digitization, networking, and intelligence. Power devices commonly use drive circuits designed with intelligent power modules (IPMs) as the core. IPMs integrate drive circuits internally and have fault detection and protection circuits for overvoltage, overcurrent, overheating, undervoltage, etc. Soft start circuits are also added to the main circuit to reduce the impact of the start-up process on the driver. The power drive unit first rectifies the input three-phase power or mains power through a three-phase full bridge rectifier circuit to obtain the corresponding DC power. After rectification, the three-phase power or mains power is used to drive the three-phase permanent magnet synchronous AC servo motor through a three-phase sine PWM voltage type inverter frequency conversion. The entire process of the power drive unit can be simply described as the AC-DC-AC process. The main topology circuit of the rectifier unit (AC-DC) is a three-phase full bridge uncontrolled rectifier circuit.

With the large-scale application of servo systems, the use, debugging, and maintenance of servo drives are important technical issues for servo drives today. More and more industrial control technology service providers have conducted in-depth technical research on servo drives.

Servo drives are an important component of modern motion control and are widely used in automation equipment such as industrial robots and CNC machining centers. Especially for servo drives used to control AC permanent magnet synchronous motors, they have become a research hotspot both domestically and internationally. The current design of communication servo drives commonly adopts a current, velocity, and position closed-loop control algorithm based on vector control. The rationality of the speed closed-loop design in this algorithm plays a crucial role in the performance of the entire servo control system, especially in terms of speed control.