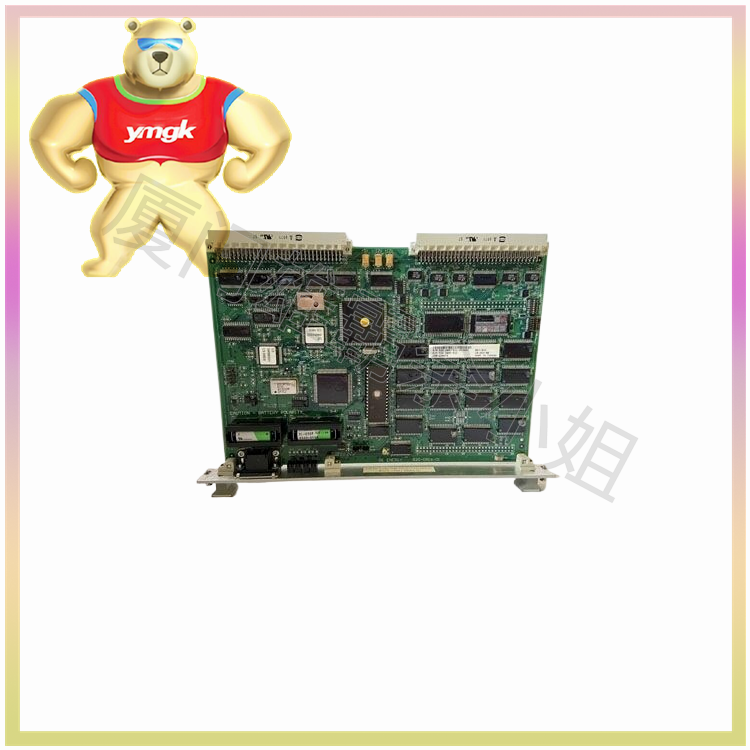

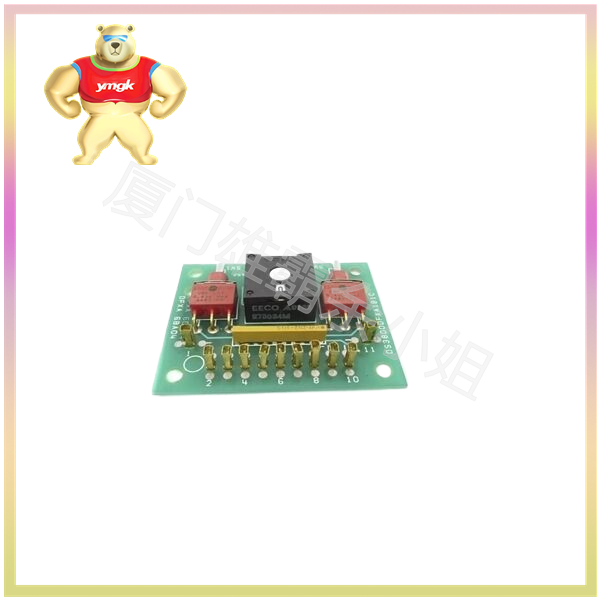

PLC signal board refers to the equipment used for input/output (I/O) signal processing in PLC systems. It is a key component in PLC systems, used to convert various physical input signals (such as switches, sensors, etc.) into digital signals, and convert digital output signals into physical outputs (such as motors, valves, etc.).

Compared to PLC signal boards, expansion modules are devices used to increase the input/output capabilities of PLC systems. Expansion modules are typically connected to the PLC host and provide additional I/O interfaces to connect more input/output signals to the PLC system.

Below, we will provide a detailed introduction to the differences between PLC signal boards and expansion modules.

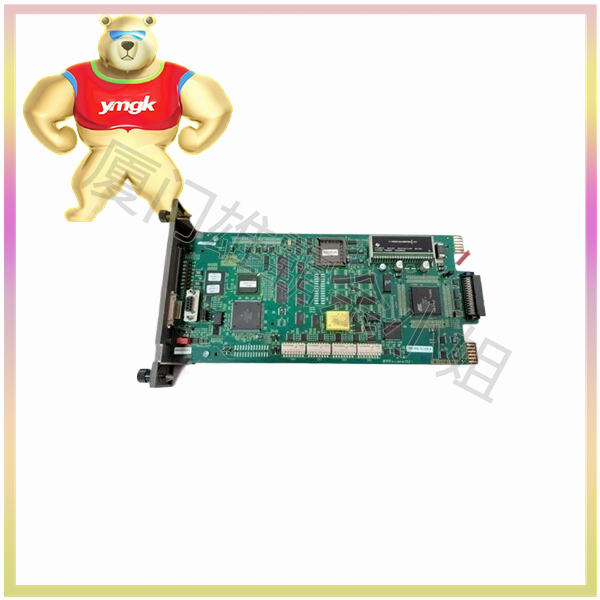

1、 PLC signal board:

The PLC signal board is mainly used for signal processing in PLC systems. It receives and processes various physical input signals such as sensors and switches, and converts them into digital signals so that the PLC host can read and process these signals. In addition, the PLC signal board also converts the digital output signals of the PLC host into physical output signals to drive corresponding actuators (such as motors, valves, etc.).

Some common features of PLC signal boards include:

Input signal processing: PLC signal board can process different types of input signals, including digital signals and analog signals. Digital signals are usually switch signals, while analog signals can be various physical quantities measured by sensors.

Output signal conversion: The PLC signal board converts the digital output signal of the PLC host into a physical output signal. These signals can be used to control various actuators, such as motors, valves, lights, etc.

Communication interface: The PLC signal board usually has an interface for communication with the PLC host, in order to send converted input/output signals to the PLC host and receive control signals sent by the PLC host.

Scalability: PLC signal boards can be added or replaced in PLC systems to meet different application requirements. You can choose different types and quantities of signal boards according to your needs.

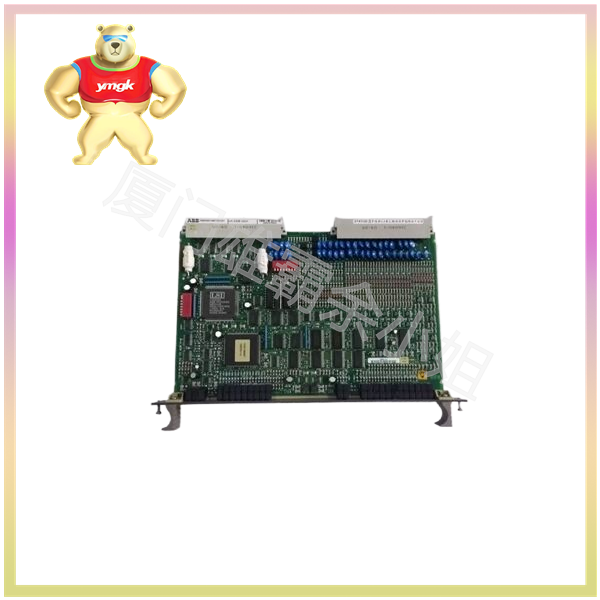

2、 Expansion module:

Expansion modules are mainly used to increase the input/output capabilities of PLC systems. It is an additional device of the PLC system that provides additional I/O interfaces to meet more input/output signal connection requirements by connecting to the PLC host.

Some common features of extension modules include:

Add I/O interface: The expansion module increases the input/output capability of the PLC system by providing additional I/O interfaces. This enables the PLC system to connect more sensors, switches, and actuators and other devices.

Modular design: Expansion modules are usually designed in a modular manner and can be easily connected to the PLC host through plug-in connections. This design makes it very convenient to increase I/O capability without affecting the operation of the entire PLC system.

Diversified interface types: Expansion modules typically provide various types of I/O interfaces, such as digital input, digital output, analog input, analog output, etc. This can meet the needs of different application scenarios.

Flexibility: Expansion modules can be flexibly configured as needed. Users can choose different types and quantities of modules to meet their specific input/output needs.

In practical applications, PLC signal boards and expansion modules are often used together. The PLC signal board processes specific logical operations related to input/output signals, while the expansion module provides additional input/output interfaces to meet larger scale input/output requirements. By using PLC signal boards and expansion modules reasonably, a powerful, high-performance, flexible and scalable PLC system can be constructed.