The basic function of a control system is to process the system in such a way that the output varies according to the changing input signal. The control system can be used to operate, monitor processes, or the entire factory.

Industrial control systems consist of various control systems currently used in different industries. These control systems include PLC, SCADA, and documents. Distributed Control Systems (DCS) and various other:

Programmable Logic Controller

Supervisory control and data acquisition (abbreviated as SCADA)

Distributed Control System

Embedded controls

PLC:

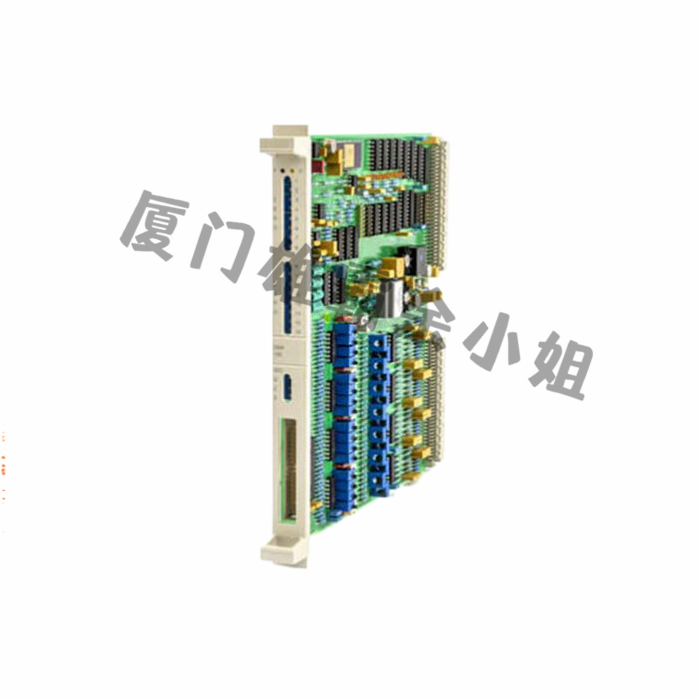

A programmable logic controller is a digital computer used for industrial process automation, such as controlling machines on factory assembly lines. PLC is designed for various input and output schemes, extended temperature range, electrical immunity, and resistance to vibration and shock.

PLC is an example of a real-time system, as the output results must be generated within a limited time to respond to input conditions, otherwise it will result in unexpected operations. The program that controls machine operation is usually stored in battery powered or non-volatile memory

PLC and programmable logic controllers are registered trademarks of Allen Bradley Company.

Supervisory control and data acquisition (SCADA) 2 stands for monitoring and data acquisition. SCADA is widely used in industry for monitoring and data acquisition of industrial processes. As the name suggests, it is not a complete control system, but rather focuses on the supervisory level.

The monitoring and data acquisition are related to the centralized solution, which consists of several subsystems such as remote telemetry devices, human-machine interfaces, programmable logic controllers or PLCs, and communication.

It is a pure software package that sits on top of hardware typically connected through programmable logic controllers (PLCs) or other commercial hardware modules.

SCADA equipment is not only used in industrial processes such as steel production, energy production (conventional and nuclear) and distribution, chemistry, but also in experimental devices such as nuclear fusion. The scale of this device ranges from several thousand to tens of thousands of input/output (I/O) channels.

Abbreviation for documents: Distributed Control System:

dcs%20ope

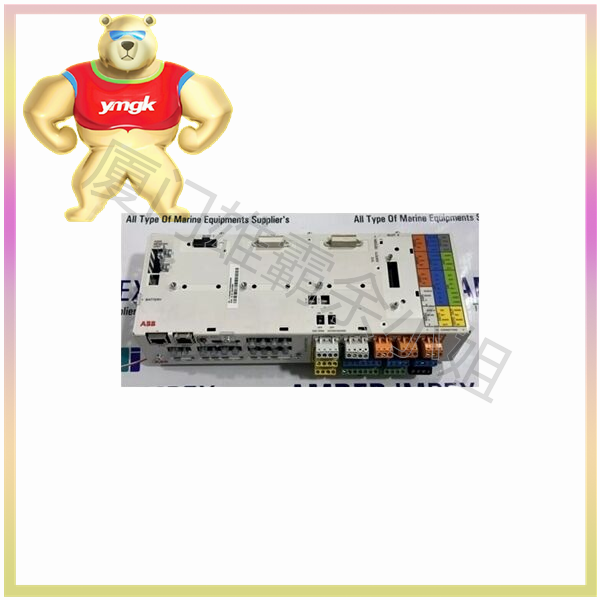

Distributed control system 5 consists of dispersed components that control all programs. As the name suggests, these controllers are distributed throughout the entire factory area. In order to reduce labor costs and accidents, human interactions are minimized.

Distributed Control System (DCS) is an instrument used to control loop systems, in which certain control methods can appear in a loop. Replace different manual and automatic control instruments to make it an easy to maintain and use device.

Embedded controls:

The abbreviation for documents is Distributed Control System, in which small components are connected to an industrial computer system through a network and controlled.