1、 The role of PLC communication module

The main function of the PLC communication module is to achieve data exchange and control operations between the PLC and other devices or systems. It serves as a link between PLC and the external world, enabling PLC to efficiently and stably transmit data and control operations through networks or other communication methods. Specifically, the role of the PLC communication module is mainly reflected in the following aspects:

Data exchange: The PLC communication module can exchange and share data in the PLC system with data in other control devices, establishing a data communication channel between the two devices. This data exchange capability is crucial for the interconnection and interoperability of equipment in the field of industrial automation. For example, through the PLC communication module, the PLC can transmit real-time data information such as temperature, humidity, flow rate, etc. to the upper computer or other control systems to achieve real-time monitoring and adjustment of the production process.

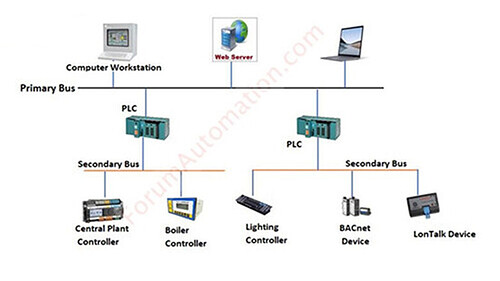

Control function: The PLC communication module can be used for control and interaction between PLCs. By networking multiple PLCs, the PLC communication module can achieve complex functions such as logical judgment and collaborative control between devices. This control function enables PLC systems to adapt to more complex and diverse industrial automation requirements. For example, on an automated production line, the PLC communication module can coordinate the work of various PLC control units to ensure the smooth operation of the production line.

Monitoring function: The PLC communication module can be used to monitor the status of the connected devices or systems. By receiving and displaying data and information from external instruments, the PLC communication module can send reminders and error messages to users, helping them discover and solve potential problems in a timely manner. This monitoring function is of great significance for improving production efficiency and reducing failure rates.

Data collection: The PLC communication module can be used for data collection. It can transmit the collected data to a computer or upper computer, and store the data locally or on cloud servers, providing support for production decision-making and data analysis for enterprises. Through the data collection function of the PLC communication module, enterprises can real-time understand various data indicators in the production process, thereby making more scientific production decisions.

2、 Function of PLC communication module

The functions of the PLC communication module are mainly reflected in the following aspects:

High speed data transmission: The PLC communication module can achieve high-speed data transmission between PLC and other devices. This data transmission capability enables PLC systems to obtain external data in real-time and respond quickly. For example, in remote monitoring and control applications, the PLC communication module can transmit real-time data of the PLC to the remote monitoring center through the network to achieve real-time monitoring and control of remote devices.

Remote monitoring and control: The PLC communication module enables users to monitor and control remote PLCs through networks or other communication methods. No matter where the user is, as long as there is a network connection, they can monitor the real-time operation status of the PLC and perform relevant control operations. This remote monitoring and control function provides enterprises with a more flexible and convenient way of device management.

Data transmission encryption: In order to protect the security of data, PLC communication modules usually support encryption functions for data transmission. The use of encryption technology can prevent data from being illegally intercepted and tampered with, ensuring the confidentiality and integrity of the data. This data encryption function is of great significance for protecting the business secrets and information security of enterprises.

Remote diagnosis and maintenance: The PLC communication module enables equipment suppliers or technical support engineers to remotely diagnose and maintain customers using the equipment through the network. Through remote diagnosis, suppliers and engineers can monitor the operational status of equipment in real-time, identify and resolve potential issues in a timely manner, reduce downtime, and improve equipment reliability and stability.

Cross platform compatibility: PLC communication modules typically support multiple communication protocols and network standards, enabling communication with PLCs and other devices from different manufacturers. This cross platform compatibility allows users to freely choose devices that suit their needs in different environments and achieve interconnectivity between devices.

3、 Summary and Prospect

The PLC communication module plays an important role in industrial automation and remote equipment management as a bridge for communication between PLC and other devices or systems. Through high-speed data transmission, remote monitoring and control, data transmission encryption, remote diagnosis and maintenance, and cross platform compatibility, PLC communication modules provide a more efficient, convenient, and secure solution for enterprise production and management. In the future, with the continuous development of technologies such as industrial Internet of Things, big data, and artificial intelligence, the functionality and performance of PLC communication modules will be further improved and perfected, bringing more innovation and breakthroughs to the fields of industrial automation and remote equipment management.