PLC (Programmable Logic Controller) is a common industrial automation control equipment with the following characteristics:

Programmable: PLC can achieve various control logics and functions through programming, realize flexible control strategies, and adapt to different control tasks.

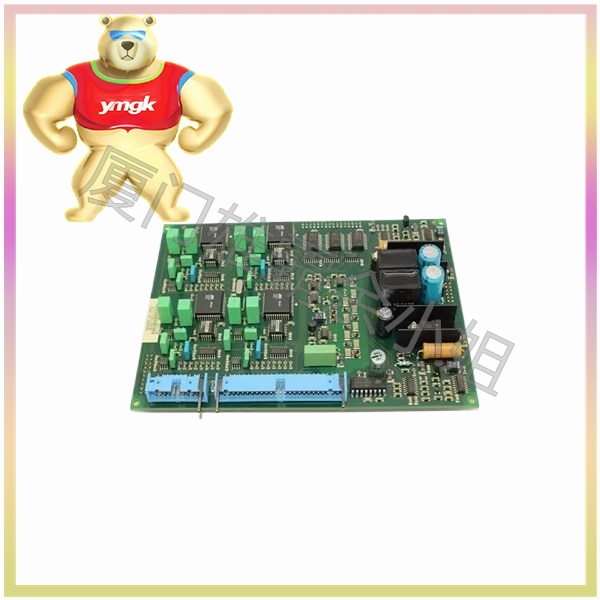

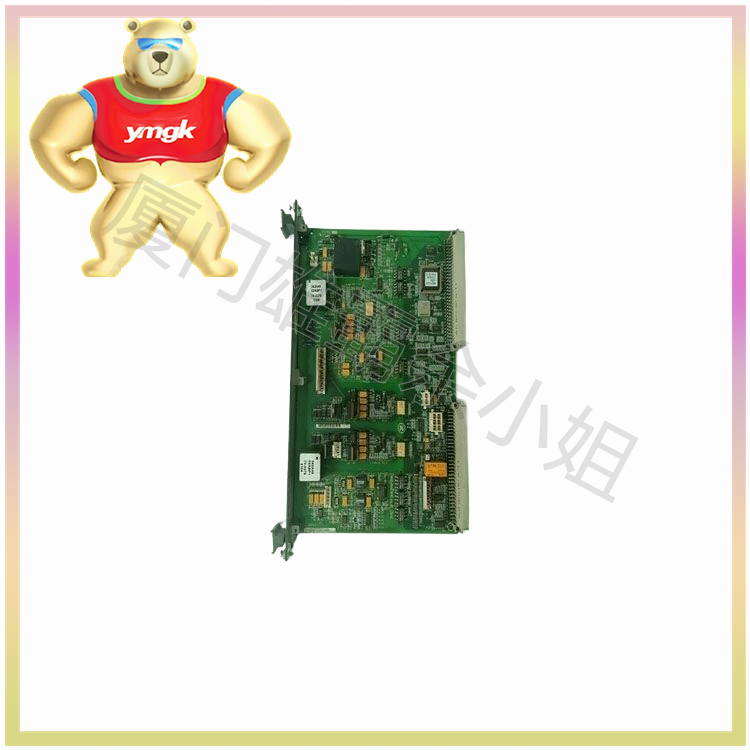

Reliability: PLC adopts industrial grade components, which have high reliability and anti-interference performance, and can operate stably for a long time in harsh industrial environments.

Real time performance: PLC has high real-time performance and response speed, which can achieve real-time control and monitoring of the production process, meeting the needs of industrial control applications.

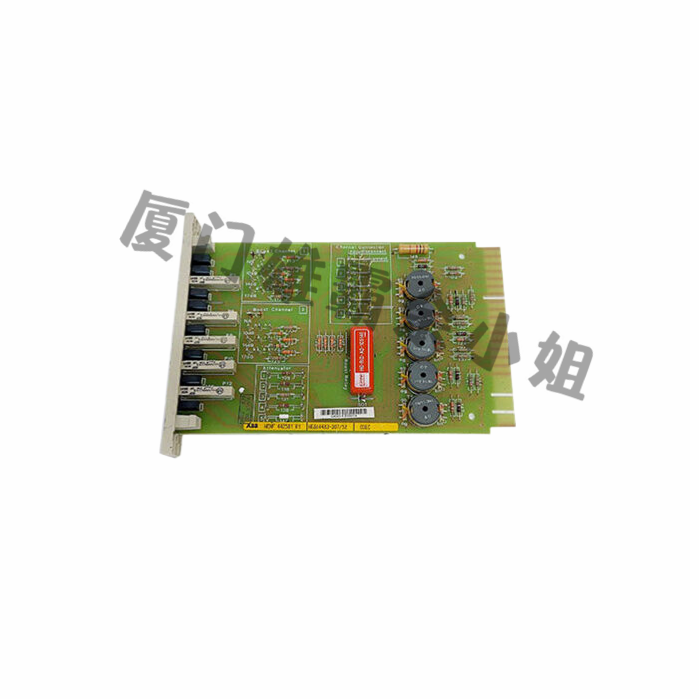

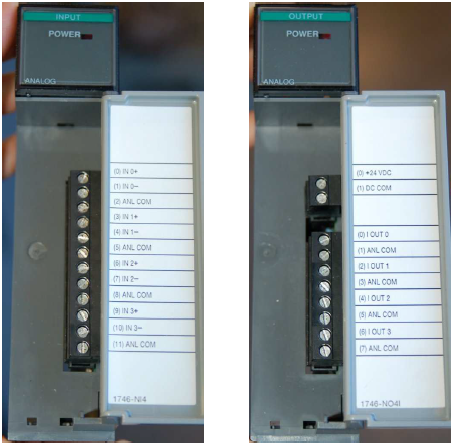

Scalability: PLC has strong scalability, which can expand its input and output ports by extending input and output modules, etc., to achieve more complex control functions.

Easy to maintain: PLC has a modular design, components are easy to replace and maintain, system debugging and maintenance are relatively simple, reducing maintenance costs.

Security: PLC has strict security protection mechanisms, including password protection, access control, etc., to ensure the security of industrial control systems.

Flexibility: PLC has high flexibility and can be customized and configured according to needs to achieve control in different application scenarios.

PLC is a powerful, reliable, real-time, and easy to maintain control device widely used in the field of industrial automation control.