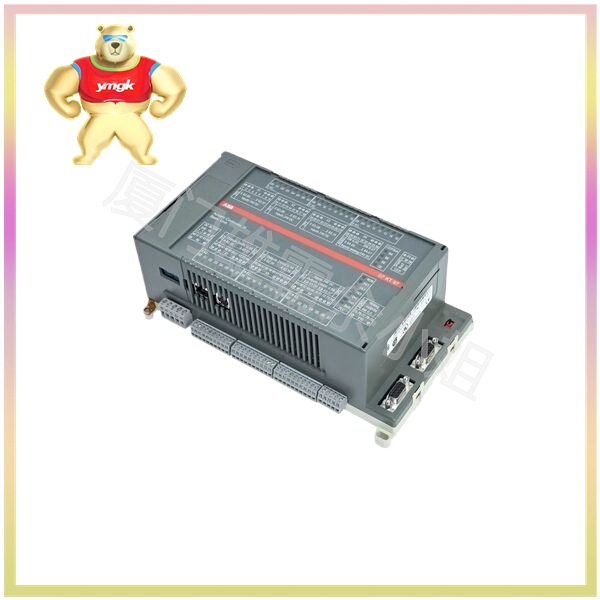

The industrial intelligent gateway launched by Wutong Bolian can connect to multiple PLCs for real-time data collection and communication work, and connect the data to cloud platforms or upper computers through 5G/4G/WIFI/Ethernet and other methods, thereby achieving remote monitoring of PLCs. Enterprises can remotely monitor the status and parameters of PLC control equipment on mobile phones or computers, receive fault alarm notifications, and achieve PLC remote control and maintenance operations for efficient and flexible digital management.

- Remote real-time monitoring: combined with 5G/4G and other wireless networks, diversified PLC protocol analysis and data acquisition and transmission are realized, and edge computing is implemented to facilitate management personnel to understand various data of equipment, such as equipment parameters and operation conditions.

- Fault alarm notification: When abnormal data is collected, management personnel will automatically receive alarm notifications on WeChat, SMS, and email, and can promptly push operation and maintenance work orders to engineers for maintenance and reduce downtime losses.

- Remote device maintenance: With the help of industrial intelligent gateways and equipment maintenance fast lines, a temporary remote maintenance channel is established. Engineers can complete remote programming, debugging, and program downloading of equipment without physically visiting the site, providing more predictive maintenance support.

- Visual data platform: PLC data can be collected into device cloud platforms, configuration software, or digital twin platforms, allowing users to locate different devices and processes at any time, achieve dynamic management, and provide visual support.