PLC, also known as Programmable Logic Controller, is a common type of electrical equipment in industrial automation sites. Since it is an electrical equipment, you must consider the issue of heat dissipation. So, how to solve the heat dissipation problem of PLC? Please share my opinion.

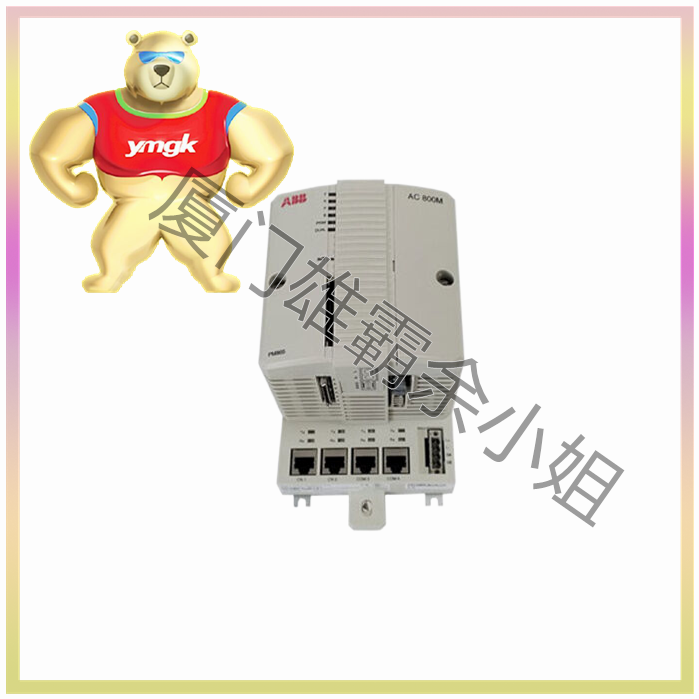

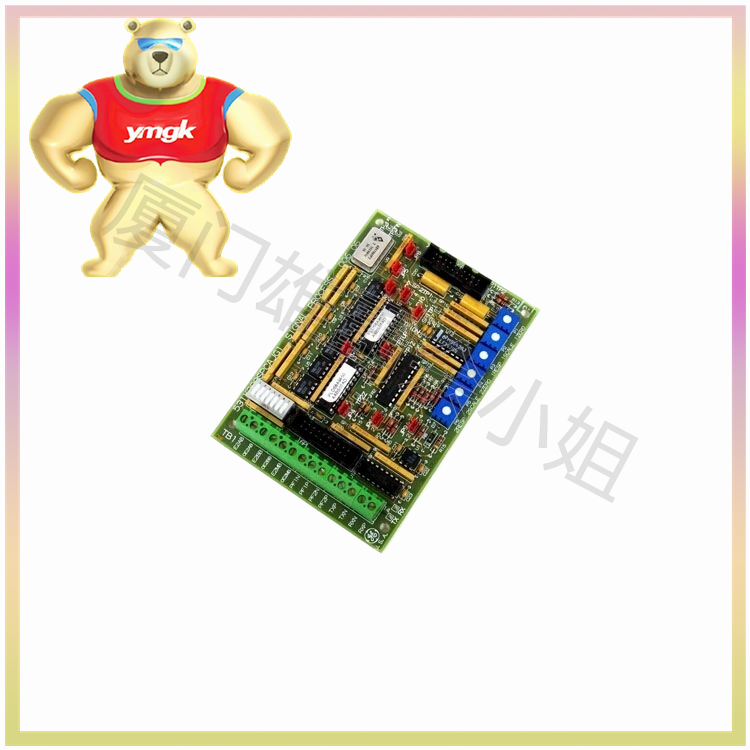

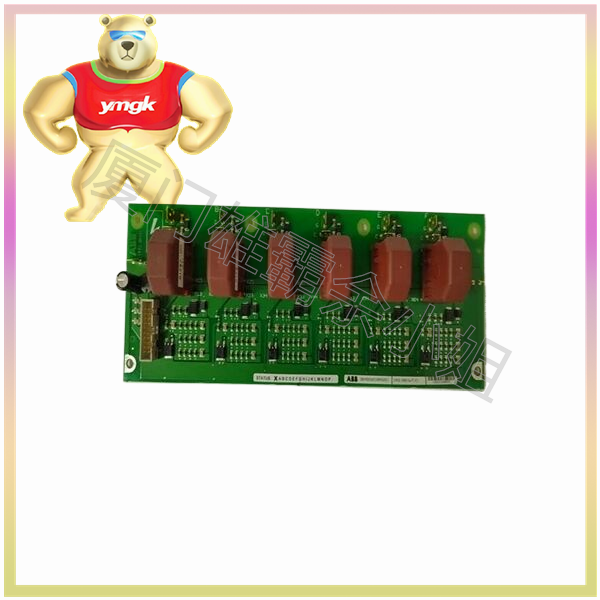

Firstly, the vast majority of PLCs do not require the addition of water-cooled or air-cooled heat sinks inside like computer cases, because PLCs themselves are not large in size and have limited internal space, making it impossible to accommodate large heat dissipation devices. Secondly, the CPUs of PLCs are mostly ARM based, with low power consumption and minimal heat generation.

Secondly, PLCs are generally integrated into control cabinets for use, which have a large space and complete air ducts to help dissipate heat. Of course, it is not ruled out that some cabinets may have fans inside. The material of the cabinet is mostly metal, with good thermal conductivity and strong heat dissipation ability. In order to cope with external heat sources, the surface of the control cabinet may be sprayed with insulation layer to hinder the interference of thermal radiation. When arranging the cabinet position, choose a cool and dry place to avoid direct sunlight.