Improve production efficiency: The motor controller can adjust the operating parameters of the motor according to actual needs, improve production efficiency, and reduce energy consumption.

Ensuring product quality: By precisely controlling the operation of the motor, the motor controller can ensure the machining accuracy and quality of the product.

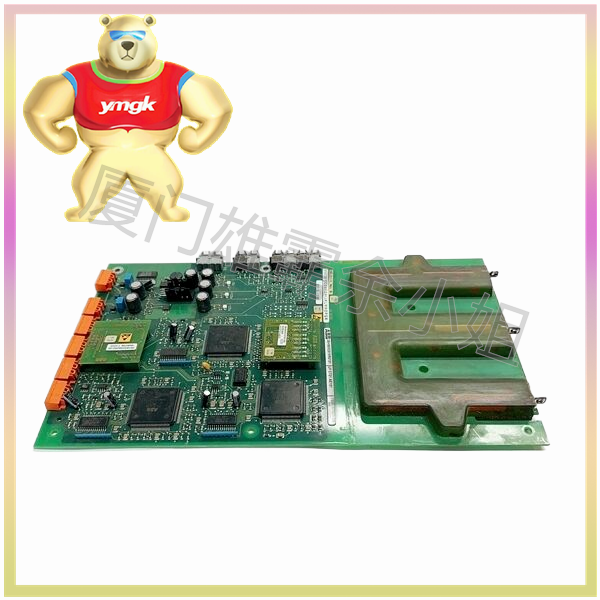

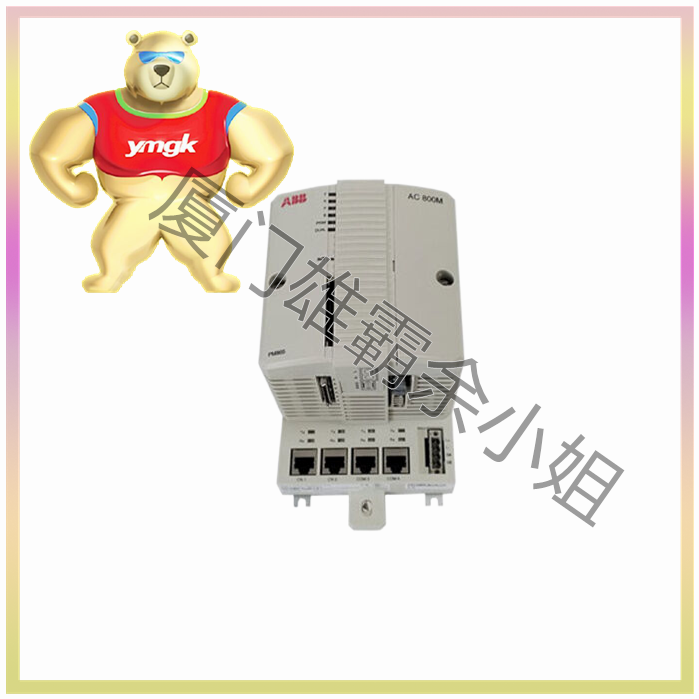

Realize automation control: The motor controller can be combined with PLC, touch screen and other equipment to achieve industrial automation control.

Energy saving and environmental protection: The motor controller can automatically adjust the operating parameters of the motor according to load changes, reduce energy consumption, and achieve energy saving and environmental protection.

Improving equipment reliability: The motor controller has protection functions such as overload protection and overheating protection, which can improve the reliability and service life of the equipment.

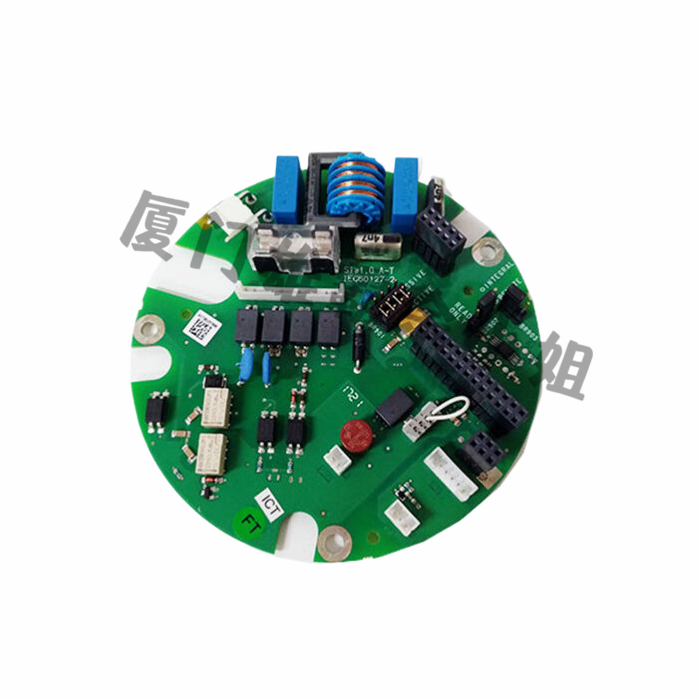

Simplify equipment structure: The motor controller integrates multiple control functions, which can simplify the structure of the equipment and reduce costs.

The motor controller, as the core component of motor operation, has a wide range of applications in modern industry and daily life. Through in-depth analysis of the composition and working principle of the motor controller, we can better understand its importance in practical applications.