Nowadays, the motion control function of PLC is becoming stronger and stronger. Arc interpolation, spiral interpolation, and electronic cam can all be easily performed. What is the difference between motion controllers and PLCs with motion control function, and what are the advantages of motion controllers in the future?

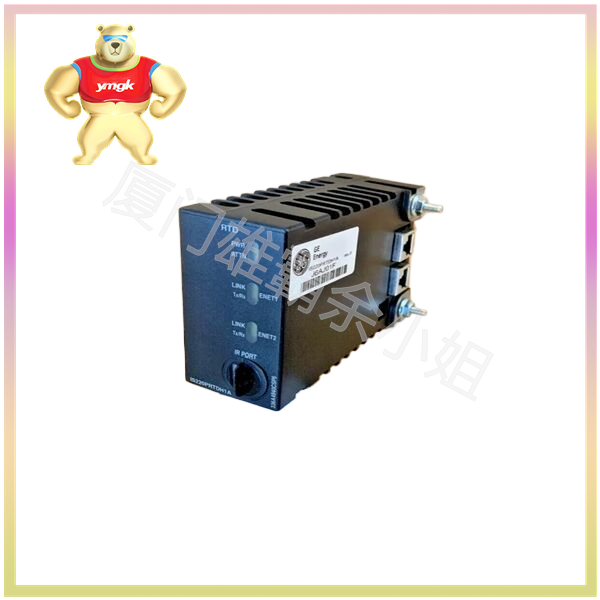

PLC and motion controllers have developed to the present day, and they are very close in terms of functionality and performance. However, in terms of form, most of them still retain their original features, namely: the motion controller is mainly oriented towards the motion control system, and the servo axis (motion axis) is its main control object; PLC is mainly aimed at logic control, and IO (Digital or Analog) is its main control object. At the same time, everyone can also see that motion controllers have strong IO capabilities, and PLCs also have motion control functions.

Below, we will analyze from the following aspects:

- From the perspective of programming languages, IEC61131-3 is already a standard configuration for these two types of controllers, and only its extended language modules can reflect their application tendencies.

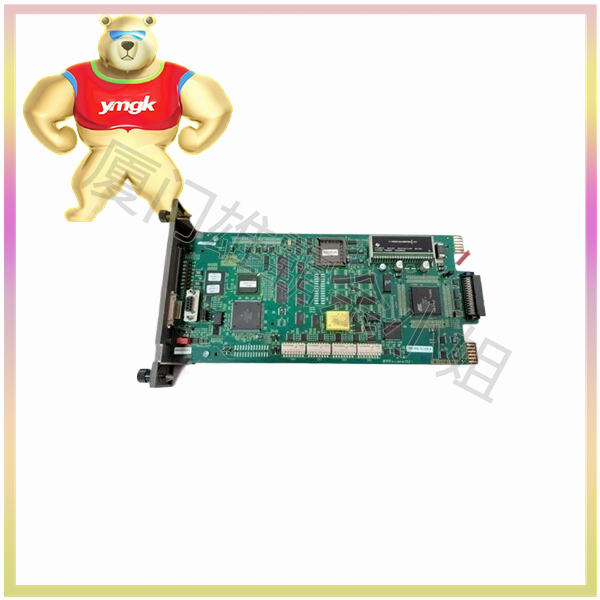

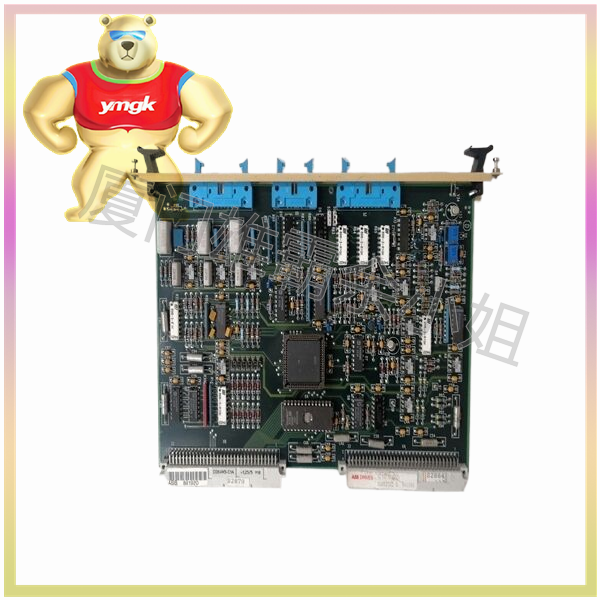

- In terms of performance, the two should be on an equal footing. PLC has developed into PAC (Programmable Automation Controller), with powerful processor performance and can be used as a multi domain controller; Motion controllers range from embedded to IPC, capable of controlling a wide range of servo axes and completing complex interpolation operations is no longer a problem.

- From the perspective of development trends, PLC and motion controllers are still developing based on their own characteristics, and there is no clear trend of being replaced by another one. For motion control, there are usually three areas: CNC, RC (Robot Control), and GMC (General Motion Control). In addition to the widespread presence of PLC in GMC, CNC and RC are still dominated by motion controllers, as IO is usually not the main focus of these two types of applications.

The real difference lies in the bias of the applications, which makes them appear different in form (port configuration, installation, wiring convenience, etc.) and in task priority processing, in order to better serve the applications they target.

In addition, cost-effectiveness is also a major consideration for user selection, meeting application needs while achieving optimal cost, which is also the reason why controllers mainly based on motion control axes and controllers mainly based on IO (PLC) still exist simultaneously. From the perspective of technological development, many companies are more inclined to configure professional controllers and edge control/computing units at Level 2 of ISA95 to achieve high cost-effectiveness, modularity, scalability, and interoperability.