In fact, a considerable number of DCS failures are caused by some daily small details. In daily applications, if we strengthen the control of these small details, we can avoid the losses caused by a considerable number of DCS failures.

So what are the things to pay attention to? Recently, the editor has carefully organized the relevant content, hoping to be helpful to everyone.

What are the sources of the malfunction?

Firstly, let’s take a look at the common sources of DCS failures.

- Human error in operation

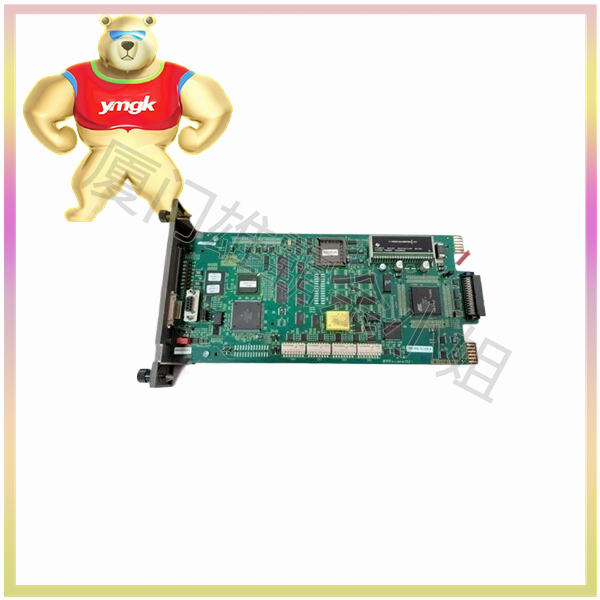

DCS technology has developed to a relatively mature level today, with a high degree of modularity. Statistics show that the probability of hardware failure is relatively low, so most DCS software and hardware failures are caused by human factors such as improper configuration and operation.

- Information Security

The industrial control field is no longer a safe haven. Click here to view industrial control security risks

- Power failure

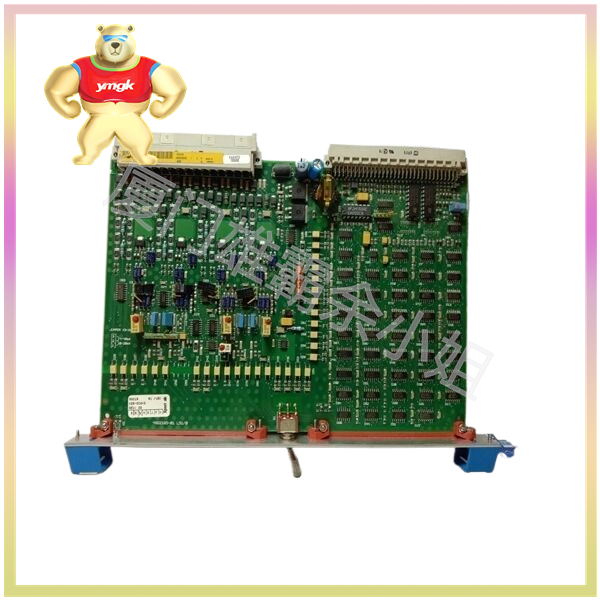

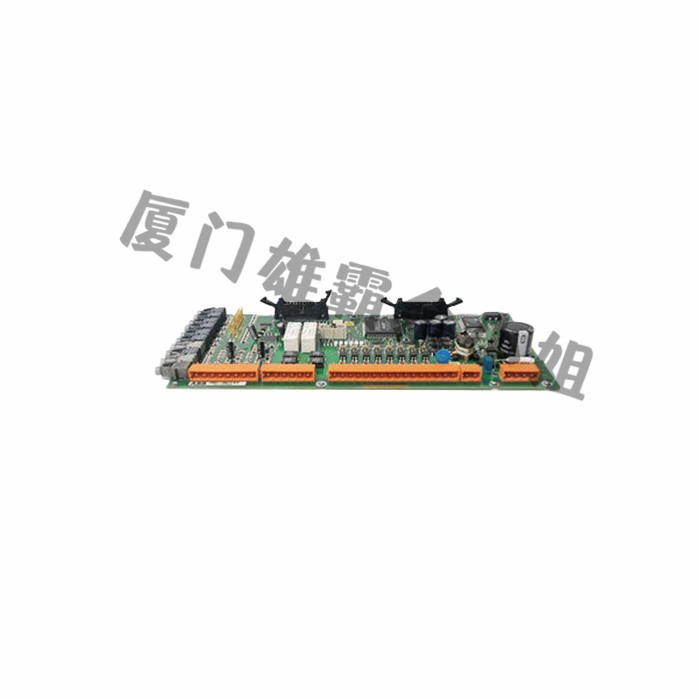

During the operation of automation instruments, any system power failure can pose a fatal threat to the DCS system. The existence of problems such as poor plug contact, inability of backup power supply to automatically switch, insufficient capacity of circuit breakers, mismatched load of automation instrument lines, power supply line accidents, and damage to circuit components can all lead to system power failures. Common impacts include power interruption, voltage sag, overvoltage, undervoltage, etc. Excessive voltage can easily burn out the board, while insufficient voltage can easily cause the board to malfunction, resulting in issues such as board fault light alarms and abnormal signal outputs. The power interruption directly caused the DCS system to malfunction.

- Electromagnetic interference

The industry characteristics of DCS application fields determine that most DCS systems are located in harsh electromagnetic environments formed by strong electrical equipment. It is often impractical to eliminate interference sources and improve the anti-interference ability of DCS systems in applications.

- Poor grounding

Poor grounding can easily cause signal jumps and signal drift in DCS when subjected to electromagnetic interference, and in severe cases, may lead to damage to the board.

- Temperature and humidity influence

High temperature, low temperature, dry, and humid working environments can have a huge impact on the system, and DCS components are easily affected by these environments, leading to failure or reduced performance. Experiments have shown that for analog cards, for every 10 ℃ temperature change, the accuracy will decrease by 0.1%; When the relative humidity exceeds 65%, a water film will form on the surface of the object, causing insulation degradation and accelerating corrosion; If the relative humidity is too low, synthetic materials are prone to brittleness, shrinkage, surface cracking, and damage.

- Impact

The surface of insulation materials is prone to static electricity accumulation: Due to the current use of large-scale integrated circuits in board circuits, chip voltage resistance is weak, so electrostatic discharge may cause board chip failure. And this kind of damage has a certain degree of concealment and latency, which is easily overlooked.

- Corrosion impact

The corrosive gases on site, as well as some buildings built by the sea (such as nuclear power plants) that are corroded by sea winds, often have a fatal impact on DCS boards and operation station computers. Industrial environments with severe corrosion often cause short circuits in electronic components on DCS boards and computer motherboards, resulting in damage to equipment hardware.

- Lightning impact

When the lightning protection device of the control room building is grounded, a strong instantaneous lightning current flows into the grounding device through the down conductor, causing local ground potential to fluctuate. If the lightning protection grounding device is independent and there is not enough distance between it and the grounding electrode of the control system, discharge (counterattack) will occur between the two, which will interfere with or damage the DCS in the control room.

- Other hazards

Including dust and rodent infestations, these can cause serious damage to DCS equipment and circuits.