Measurement principle of tension sensor

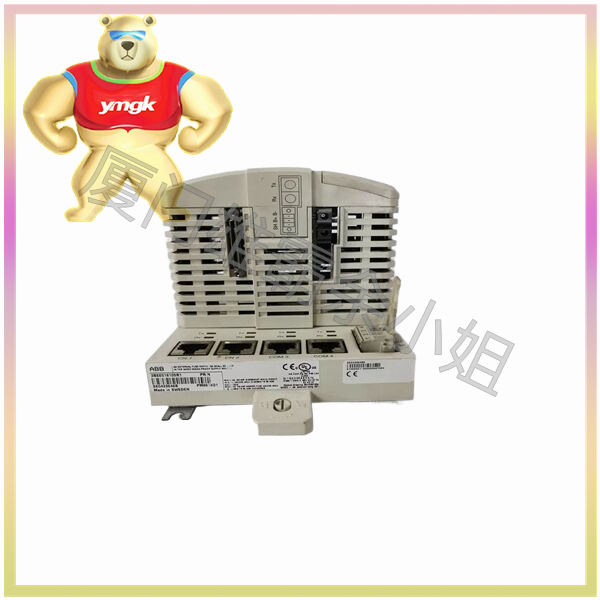

The measurement principle of tension sensor: The tension sensor is placed under the support seats on both sides of the paper guide roller, connected to the signal amplifier through a junction box, and measures the tension in the horizontal direction

FR=Tx(cosβ-cosα)

FV=Tx(sinα-sinβ)+FT

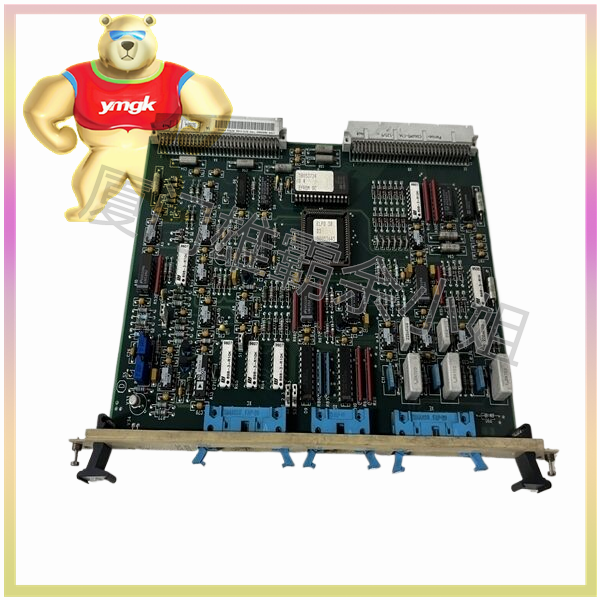

The tension sensor can measure FR to calculate the tension value of the paper web. The tension sensor is made of a special rigid material. The primary and secondary coils of the tension sensor are correctly passed through the four holes of the sensor. The primary coil is the excitation coil, and the secondary coil is the induction coil. Under normal circumstances, there is no induced voltage generated in the secondary coil. When a horizontal tension T is applied to the sensor, the secondary coil induces a corresponding voltage. The direction of tension changes, and the polarity of the voltage generated by the secondary coil also changes.

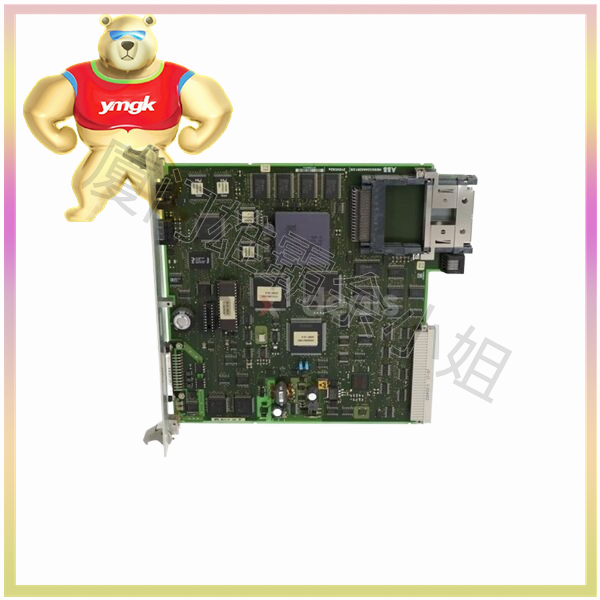

On the production line of the paper machine, the paper will stretch and contract at the glue application area, and tension control is necessary to eliminate the influence of glue application. Paper web fluctuations and paper breakage often occur in the pressing, sizing, and post drying sections, as well as in the post drying and calendering sections, requiring tension control.

The control of tension can be achieved through both direct control and indirect control. Direct control is when the actual tension value is measured by a tension sensor to control the transmission speed, while indirect control is when the motor speed is measured to calculate the tension paper. After comparison, the motor speed is controlled based on the magnitude of the difference. Generally, indirect control and direct control are combined.

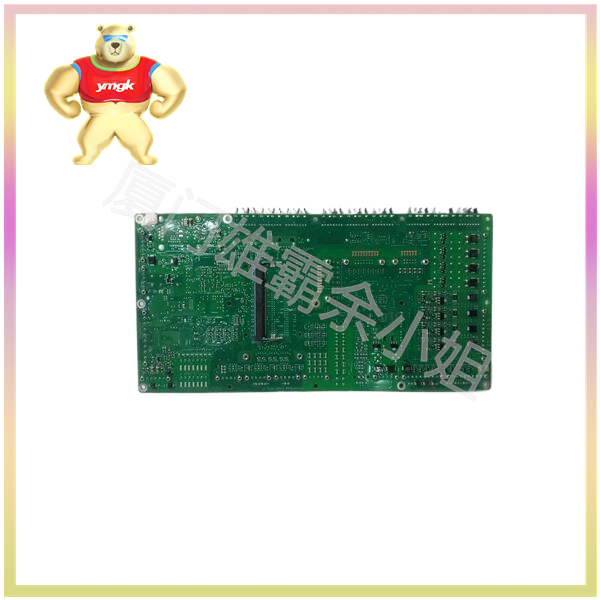

At the initial stage, it is controlled by a tension sensor, and when it is approaching, it switches to indirect tension control.