PLC input signal types can be divided into the following two categories:

Digital input signal: Digital input signal refers to a signal with only two states, usually represented as 0 or 1, such as switch signal, button signal, sensor signal, etc. The digital input signal can be directly connected to the digital input module and collected and processed by the PLC. The processing of digital input signals is simple and suitable for binary control of external devices.

Analog input signal: Analog input signal refers to a signal whose magnitude can continuously change, such as temperature signal, pressure signal, flow signal, etc. The analog input signal needs to undergo A/D conversion through the analog input module to convert the analog signal into a digital signal, which is then collected and processed by the PLC. The processing of analog input signals is relatively complex and suitable for precise control and adjustment of external devices. In practical industrial control, PLC usually needs to process various types of digital and analog signals, such as sensor signals, button signals, temperature signals, pressure signals, flow signals, speed signals, position signals, etc. Select different input modules for data acquisition and processing according to actual needs, and then use PLC for logic processing and control output modules to control external devices.

PLC has no input signal

If the PLC does not have input signals, it cannot control and regulate external devices. The input signals of PLC usually come from external devices such as sensors, buttons, switches, etc. Without the input signals of these devices, PLC cannot collect and process signals, and therefore cannot control and adjust external devices. In practical industrial control, if the PLC does not have an input signal, the following points usually need to be checked:

Check if the input device is functioning properly: If the input device is faulty or not connected, signals cannot be collected and the PLC cannot control or adjust it.

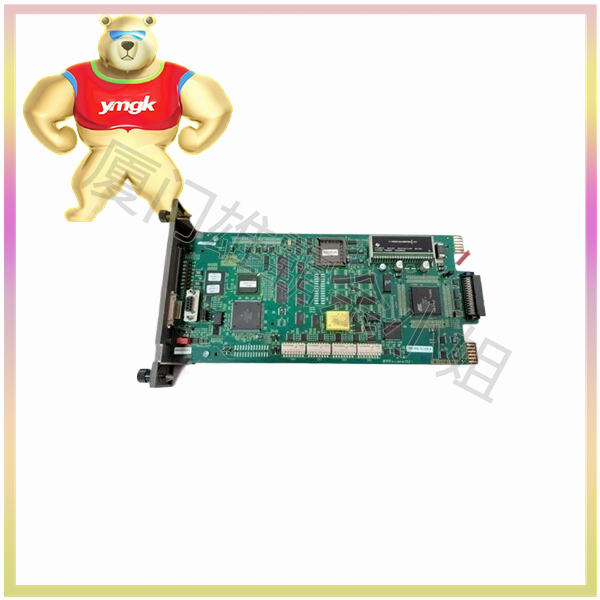

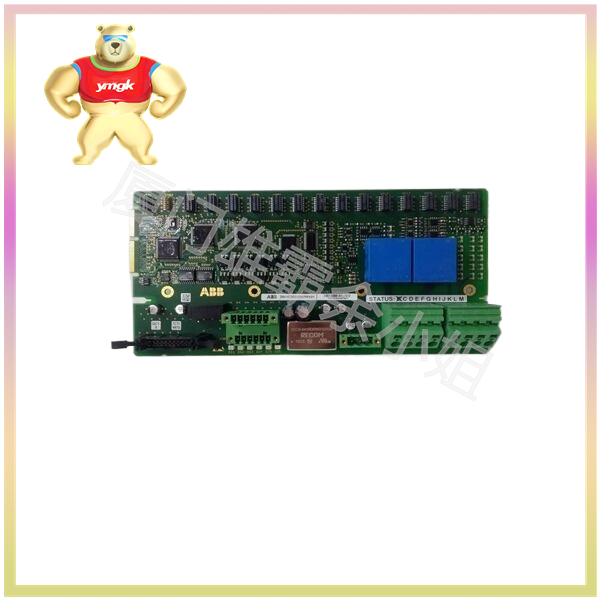

Check if the input module is functioning properly: If the input module is faulty or not connected, the signal cannot be converted into digital or analog signals within the PLC, and the PLC cannot collect and process them.

Check if the PLC program is normal: If the PLC program is incorrect or not started, it cannot perform logical processing and control output modules to control external devices. If all the above issues have been resolved and there is still no input signal, further inspection of the PLC hardware, such as power supply, CPU, communication ports, etc., is required. If the problem cannot be solved, it is necessary to contact the PLC manufacturer or professional maintenance personnel for repair.