The programmable logic controller 20 drum or PLC is a universal controller suitable for various types of process control applications. PLC modules have different I/O functions, and there are also different types of I/O modules.

A microcontroller (brick) is a fixed I/O module that is connected to PLC equipment and has a fixed number of I/O ports. Each input line has a corresponding output line, which is fixed.

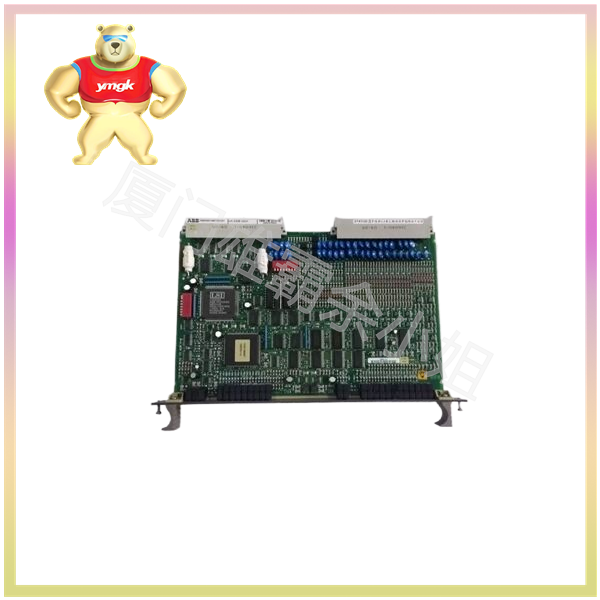

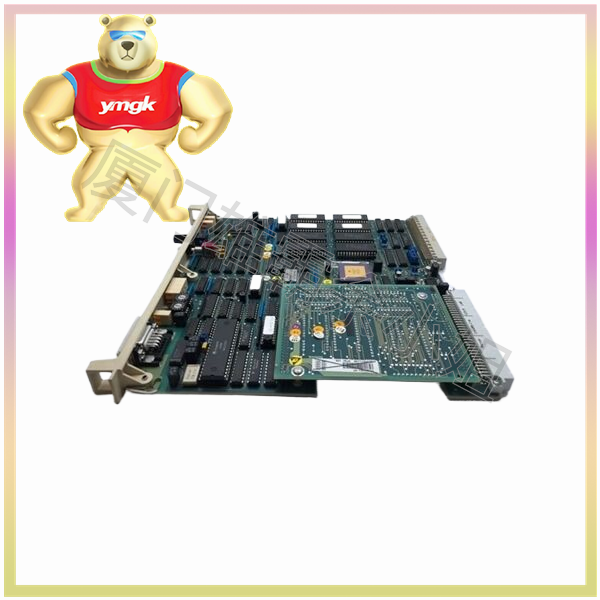

Modular (rack mounted) PLCs can be replaced and removed from the PLC rack. If any malfunction occurs and maintenance is required, the card can be removed and reconnected correctly without the need to replace the entire PLC. Specific I/O cards can be selected for custom applications.

Some PLCs can even replace the rack during operation without cutting off the power supply. There are analog I/O cards, discrete I/O cards, and remote interface I/O in the rack.

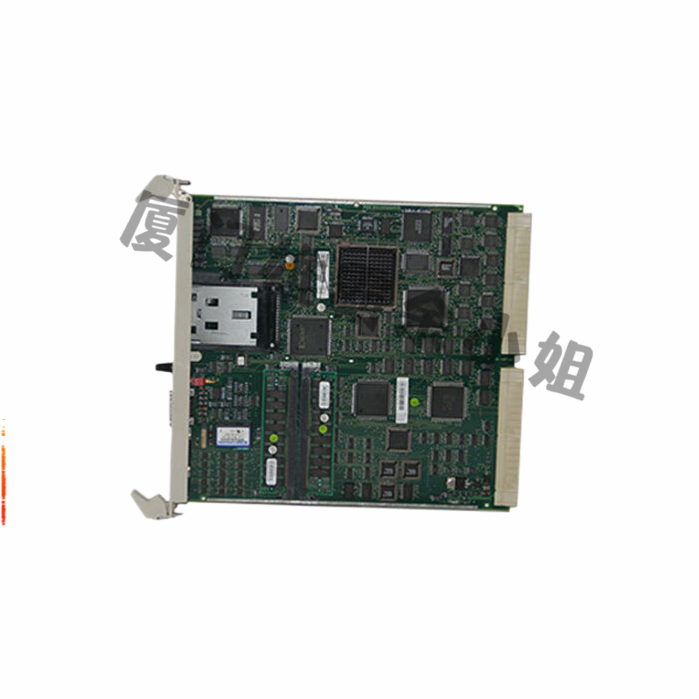

If some PLCs lack slots, remote I/O slots can be used to connect one PLC to another.

There will be a Remote I/O interface rack, where the host’s remote I/O interface sends programming instructions to the slave PLC, processes the output, and returns it to the host’s I/O interface through the slave’s Remote interface. This way, additional racks can be implemented.

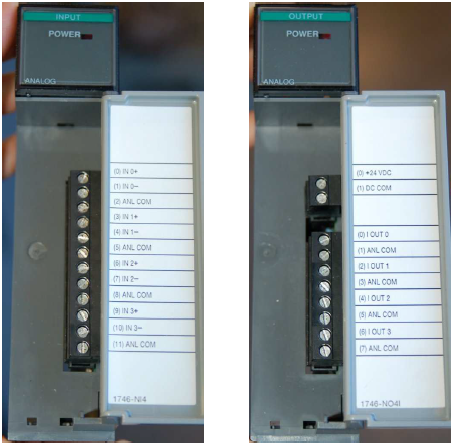

Discrete I/O

Discrete I/O has only two operating states: on/off. Process switches, button switches, limit switches, and proximity switches are all examples of discrete sensing devices. The following figure shows the discrete input connection:

The output is emitted by a PLC using LED, and when light is emitted, there is a light sensing device on the other end. It senses light signals and opens circuits. Alternatively, small electromechanical relays can be used instead of optoelectronic isolated semiconductor switching elements, such as transistors (DC) or thyristors (AC).

Each output channel has its own optocoupler, driven by its own unique memory register bit in the PLC memory. The discrete output card of PLC often has 4, 8, 16, or 32 channels.

Analog input/output

However, modern PLC technology is powerful enough to support the measurement, processing, and output of analog (continuously variable) signals. All PLC devices are digital devices used to connect continuous AC power to the PLC. AC power will be converted into numbers. Each PLC uses an analog-to-digital converter (ADC) internally to convert analog input values into digital values. And use a DAC digital to analog converter to convert digital internal commands into analog outputs. The range of most analog inputs is 4-20mA.