In a distributed control system (DCS), the I/O (input/output) module is an important component that interfaces between the control system and field devices such as sensors and actuators. These modules are crucial for collecting data from the field and sending control signals to devices. The different types of I/O modules available in DCS systems include:

- Digital Input (DI) module

Purpose: To receive binary signals from on-site devices.

Application: Read the status of switches, buttons, limit switches, and digital sensors.

Function: It can detect the presence or absence of voltage signals. - Digital Output (DO) Module

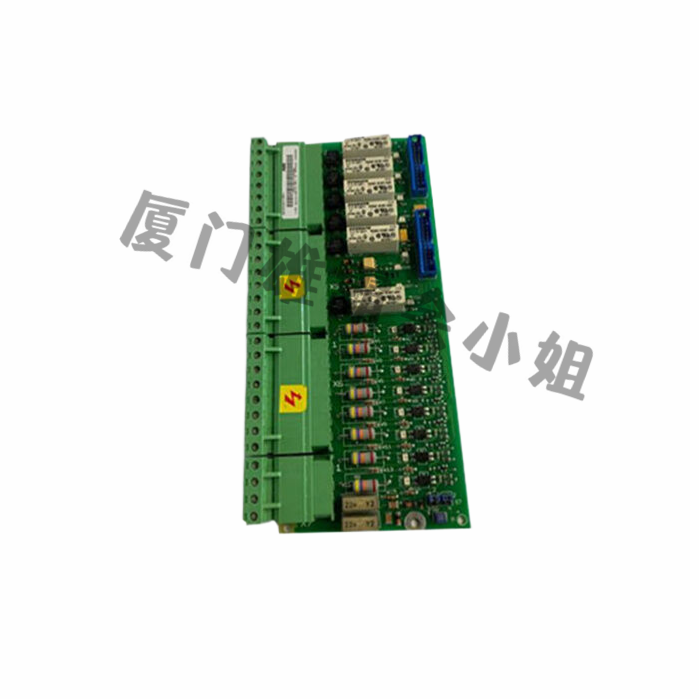

Purpose: To send binary signals to on-site devices.

Application: Control relays, solenoids, lights, and other binary actuators.

Function: External devices can be turned on or off. - Analog Input (AI) Module

Purpose: To receive continuous signals from on-site equipment.

Application: Read measurement values from temperature sensors, pressure sensors, flow meters, and other analog devices.

Features: Can handle various signal ranges (e.g. 0-10V, 4-20mA). - Analog Output (AO) module

Purpose: To send continuous control signals to on-site equipment.

Application: Control valves and actuators such as variable frequency drives (VFDs).

Features: Output various signal ranges (e.g. 0-10V, 4-20mA). - Pulse Input (PI) Module

Purpose: To receive pulse signals from on-site equipment.

Application: Pulse counting for flow meters, encoders, and tachometers.

Features: Can count and measure the frequency or duration of pulses. - Pulse output (PO) module

Purpose: To send pulse signals to on-site equipment.

Application: Control stepper motors and pulse width modulation (PWM) devices.

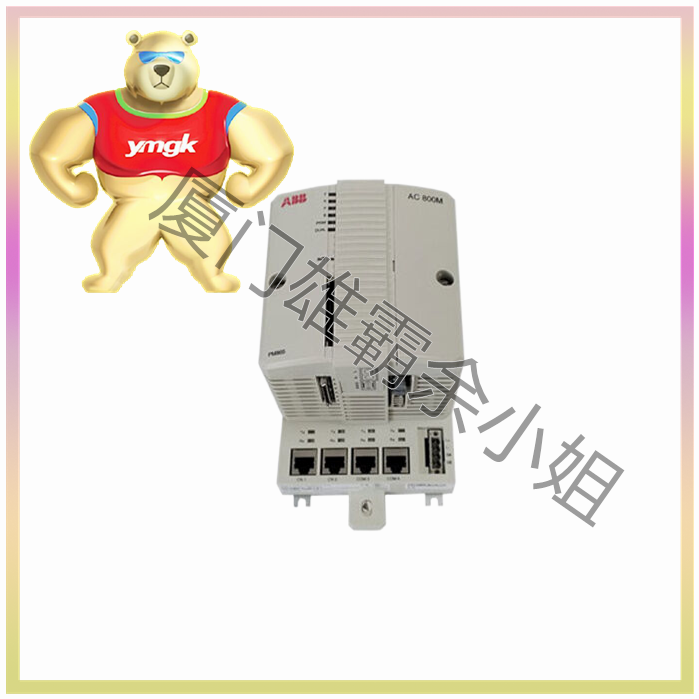

Characteristics: Generate precise pulse signals for control purposes. - Communication module

Purpose: To facilitate communication between DCS and other systems or devices.

Application: Integrate DCS with PLC, SCADA systems, third-party devices, or other DCS systems.

Type: Ethernet PROFIBUS、Modbus、HART、 Fieldbus. - Special function modules

Purpose: To perform specific functions not covered by standard I/O modules.

Applications: signal conditioning, safety system interface, event sequence recording.

For example, RTD modules for resistance temperature detectors and thermocouple modules for temperature measurement. - Redundant I/O modules

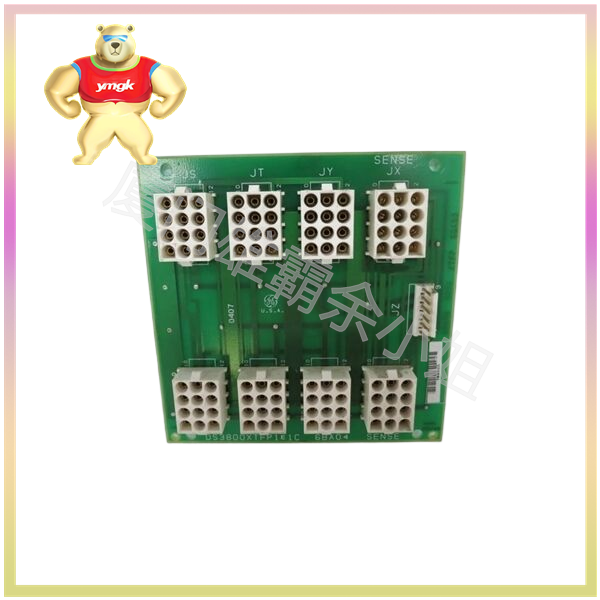

Purpose: To provide redundancy for critical applications that require high availability and reliability.

Application: Ensure that the module can continue to operate even in the event of a malfunction.

Features: Redundant I/O channels and hot swappable functionality. - Intelligent I/O module

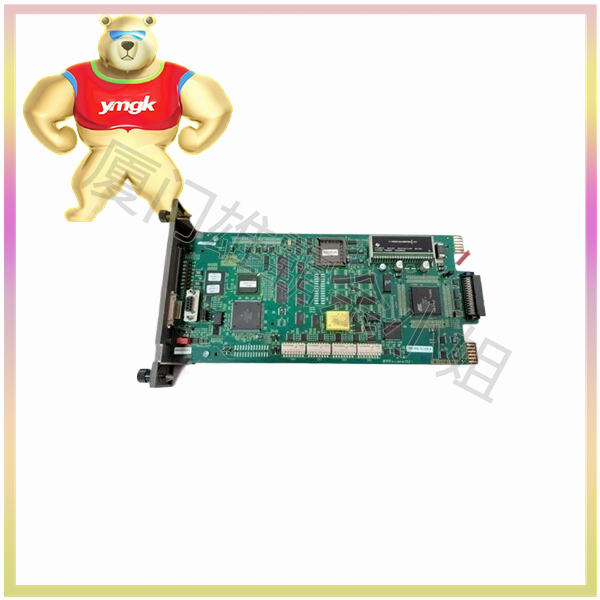

Purpose: To combine I/O functionality with processing capabilities for local data processing and diagnostics.

Applications: Advanced diagnostics, predictive maintenance, and local control.

Features: Built in intelligence for pre-processing data and health monitoring of on-site devices.

Each type of I/O module is designed to meet specific requirements and applications within DCS, ensuring the flexibility, scalability, and reliability of industrial automation and control systems.