Programmable Logic Controller (PLC) is a general-purpose control system that accepts inputs from various sources, such as buttons, temperature, flow sensors, pressure sensors, limit switches, etc. It can send signals to devices such as load relays, motor starters, stepper motors, solenoid valves, and even servo drives.

PLC is designed to perform logic functions previously completed by electromechanical relays.

Components of PLC

All programmable logic controllers (PLCs) consist of four basic components. They are

Power Supply

Input/output section

Processor section

Program Design Department

The programs used in discrete part manufacturing and process manufacturing are stored in memory and can be retrieved when needed.

The components of a programmable logic controller are interconnected and work together to allow the controller to accept inputs from various sensors, make logical decisions according to programming, and control outputs such as motors, solenoids, drivers, and valve starters.

power supply

The power supply provides the basic voltage level required for PLC operation. It also supplies power to the I/O module. The power supply can be an independent unit or integrated into the power supply section. It receives input voltage (usually 120 VAC or 240 VAC) and adjusts the voltage as needed (usually 5 VDC to 32 VDC).

The power supply must provide a constant output voltage without transient voltage spikes and other electrical noise. When the power is removed or turned off, the internal battery in the programmable logic controller charges to prevent memory loss.

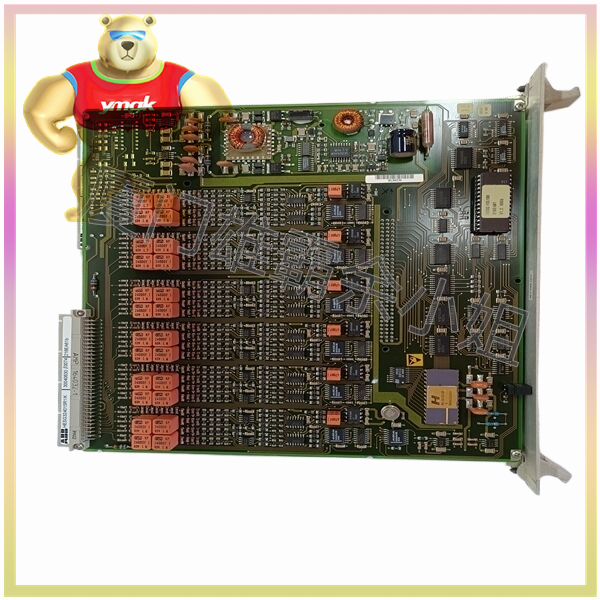

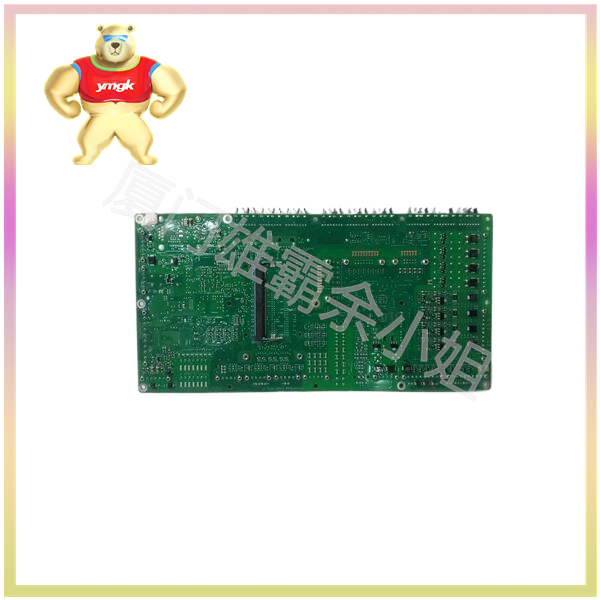

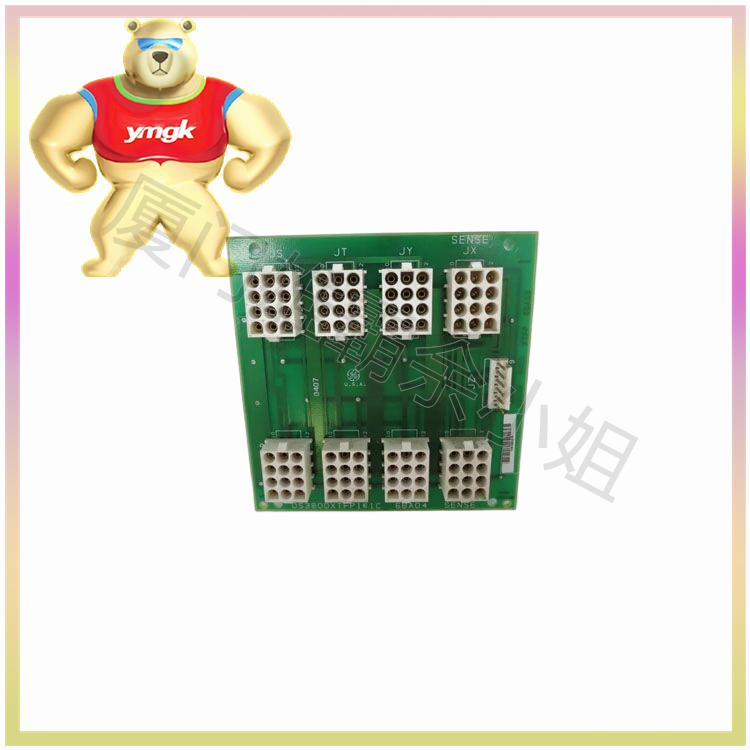

Input/Output (I/O) section

The input/output (I/O) part serves as the eyes, ears, and hands of the programmable logic controller. The input section is used to receive information from buttons, temperature switches, pressure switches, photoelectric, proximity switches, and other sensors.

The input section converts the received signal from high voltage to low-power data signal and sends it to the processor section. The processor receives input signals from input devices and compares them with the program.

The output section receives low-power digital signals from the processor and converts them into high-power pulses. These high-power pulses can provide power for industrial loads that can illuminate, grip, move, rotate, extend, release, and do other necessary things.

The I/O part can be set on the programmable logic controller or in the expansion module.

The programmable logic controller package includes onboard I/O as a permanent component. Expansion modules are modular units, which means we can remove components. Modular components include inputs, outputs, or combinations of inputs and outputs.

Onboard I/O typically has a fixed number of inputs and outputs that define the limitations of the programmable logic controller. For example, a small programmable logic controller can have up to 16 inputs and 8 outputs. This means that the controller can handle up to 16 inputs and 8 outputs.

We can increase or expand the number of inputs and outputs of PLC by adding extension modules

The programmable logic controller using extension modules allows for changing the total number of inputs and/or outputs by modifying or adding modules. Individual machines and small systems typically use onboard programmable logic controllers.

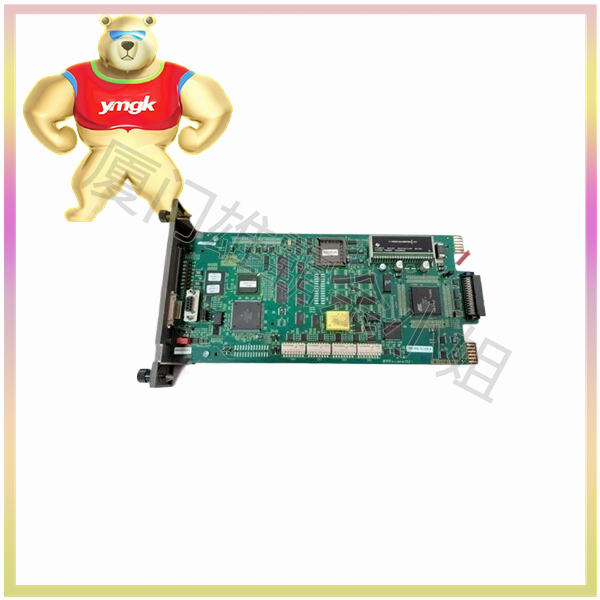

Processor section

The processor part of a programmable logic controller is the part that organizes all control activities by receiving inputs, making logical decisions based on the program, and controlling outputs.

The processor part, also known as the central processing unit, is the brain of a programmable logic controller (CPU).

The three wire transistor output sensor uses NPN or PNP transistors to control the load.

Central Processing Unit

The processor section makes decisions necessary for observing, monitoring, and controlling field devices connected to input/output modules

The PLC central processing unit is built into a single element fixed PLC controller, while modular framework categories typically use plugins.

Central processing units, control systems, and computers are all names used by different manufacturers to refer to similar devices that perform similar tasks.

CPUs vary in processing/operating speed and storage options.

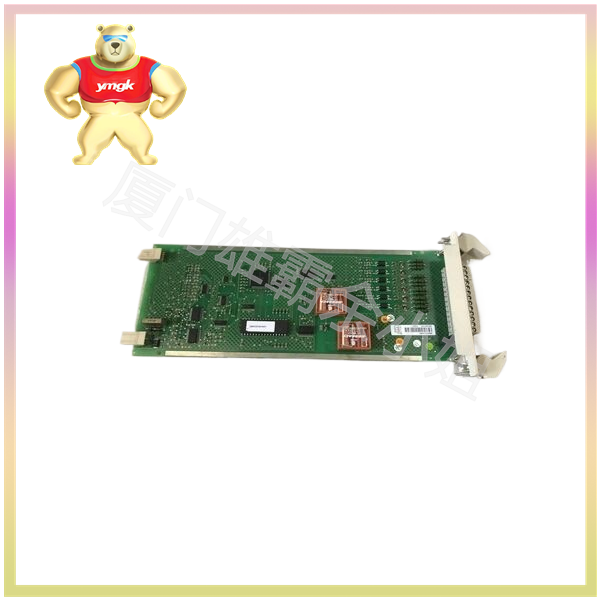

Programming section

The programming part of a programmable logic controller is the part that allows input to the controller through a keyboard.

Accurate step-by-step instructions must be provided to the processor. Loading, setting, resetting, clearing, entering, moving, and starting timing must all communicate with the processor.

Programming equipment

The size, capabilities, and functions of programming devices vary. Programming devices can be simple small text displays or complex color displays with monitoring and graphics capabilities.

Programming devices can be simple small text displays or complex color displays with monitoring and graphics capabilities.