Fixed PLC and

Modular PLC

There are two main types of programmable logic controllers (PLCs) that are used in industrial automation applications and differ in their properties and purposes.

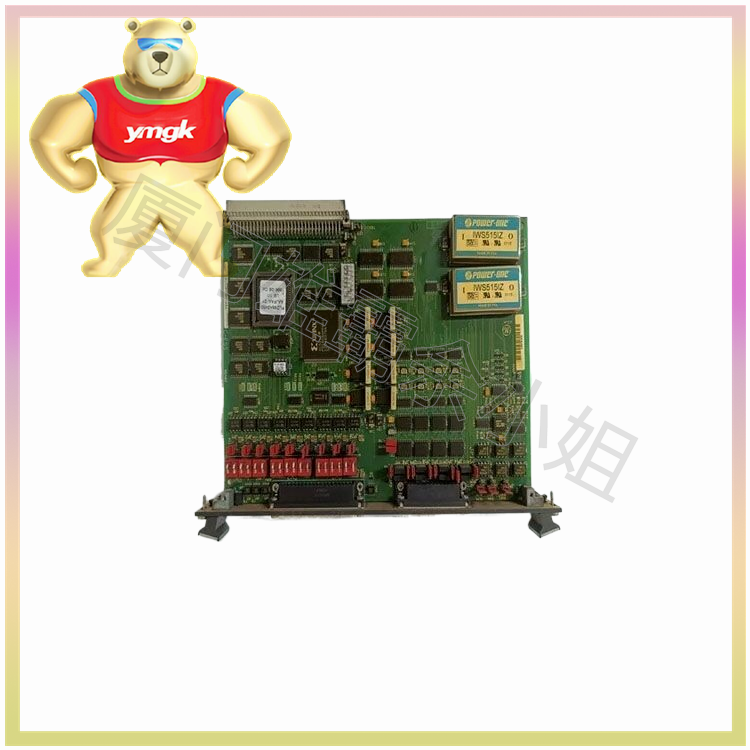

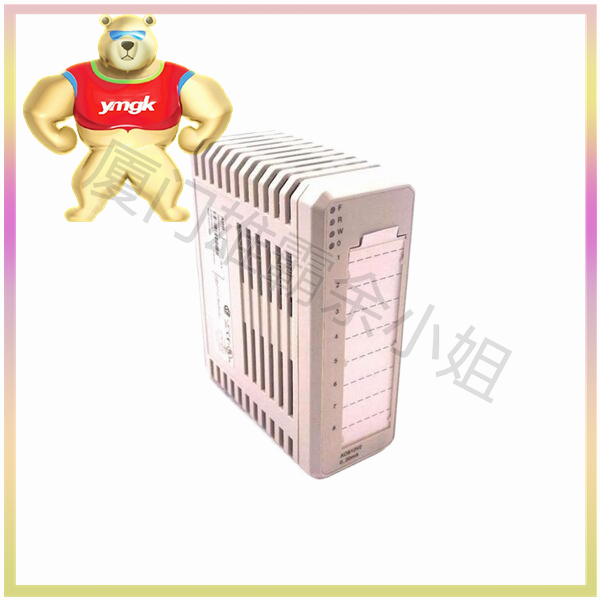

Fixed PLC

A treatment bed or clinical model PLC is a descriptive PLC with input and output capabilities, integrated into a single package called a fixed PLC.

This means that the I/O points are limited, and any additional ones are impossible because they are designed and limited by the manufacturer.

The main features include:

comprehensive

It is an integrated device that integrates all peripherals and circuits, CPU, power supply, and communication interfaces into one module.

Limited scalability

Due to their fixed I/O, these PLCs are ideal for small applications where control requirements are not expected to expand or change in the future.

Cost effectiveness

Fixed PLCs are usually cheaper than modular PLCs, and it is recommended to use modular PLCs in areas with lower I/O requirements.

maintain

When the components that fix the PLC are damaged, sometimes more problems may arise because the entire fixture may need to be replaced, which will take longer.

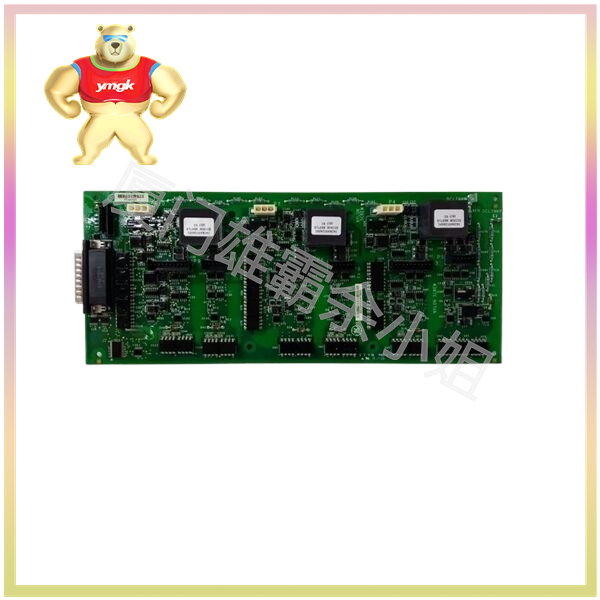

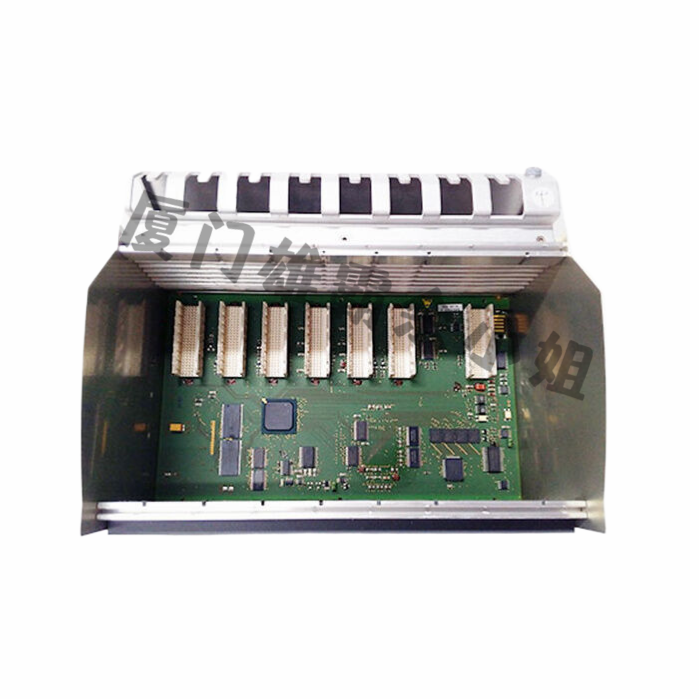

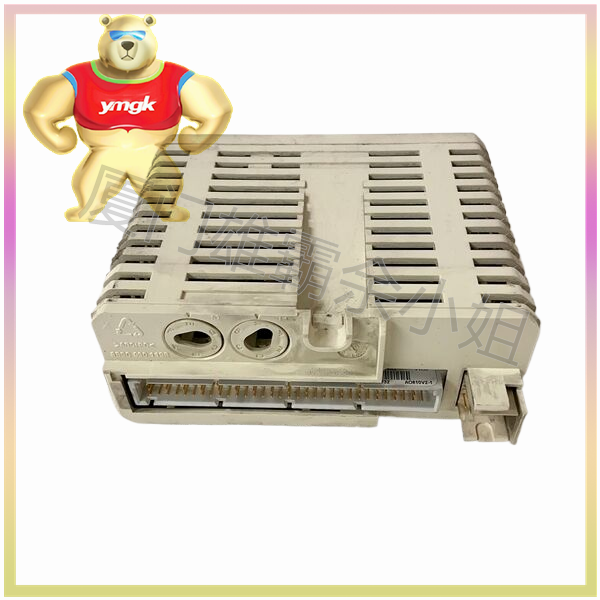

Modular PLC

Rack mounted PLCs are other types of modular PLCs that have independent CPU, power, and I/O interface modules.

It has been proven that this design is more solvable, flexible, and scalable.

The main features include:

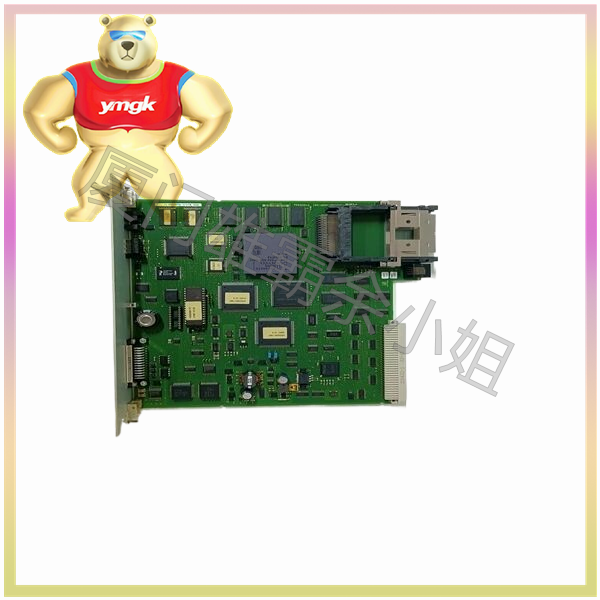

Expansibility

The scalability of the system is very easy, as users can upgrade or downgrade I/O modules according to the constantly growing application requirements. That’s why modular PLCs are particularly suitable for complex systems in industrial manufacturing environments.

Easier fault detection and maintenance

The elements of each module are independent, which helps determine the location of the problem.

In the event of a problem with one of the modules, it is usually included and easy to modify, thereby minimizing downtime to the greatest extent possible.

Higher performance

Modular PLCs have higher capabilities to control more I/O points and more complex processes, as they can be expanded by adding more modules to the system, making them recommended for use in complex industrial processes.

Cost considerations

Compared with traditional programmable logic controllers, modular programmable logic controllers are more cost-effective in the long run due to their flexibility in expansion and ease of maintenance, as they increase the components and capacity included in the programmable logic controller.

Therefore, it can be concluded that the decision to integrate fixed or modular PLCs mainly comes down to several factors, such as the size of the production line, cost considerations, and expected scalability. Fixed PLCs are suitable for applications that are very simple and unlikely to change over time, while modular PLCs are suitable for complex environments in large industries.