The price of general I/O modules accounts for more than half of the price of PLCs. The I/O modules of PLC include switch I/O modules, analog I/O modules, and various special function modules. Different I/O modules have different circuits and functions, which directly affect the application scope and price of PLC, and should be selected according to actual needs.

(1) Selection of switch I/O module

- Selection of switch input module

The switch input module is used to receive switch signals from on-site input devices, convert the signals into low-voltage signals received internally by the PLC, and achieve electrical isolation between internal and external signals of the PLC. When making a choice, the following aspects should be considered:

1) Type and voltage level of input signal

There are three types of switch input modules: DC input, AC input, and AC/DC input. The selection is mainly based on on-site input signals and surrounding environmental factors. The delay time of the DC input module is relatively short, and it can also be directly connected to electronic input devices such as proximity switches and photoelectric switches; The communication input module has good reliability and is suitable for use in harsh environments with oil mist and dust.

The voltage levels of the input signal of the switch input module include DC 5V, 12V, 24V, 48V, 60V, etc; Exchange 110V, 220V, etc. The selection is mainly based on the distance between the on-site input device and the input module. Generally, 5V, 12V, and 24V are used for transmission distances that are relatively close, such as 5V input modules, which should not exceed a maximum distance of 10 meters. Modules with higher input voltage levels should be selected for those that are far away.

2) Input wiring method

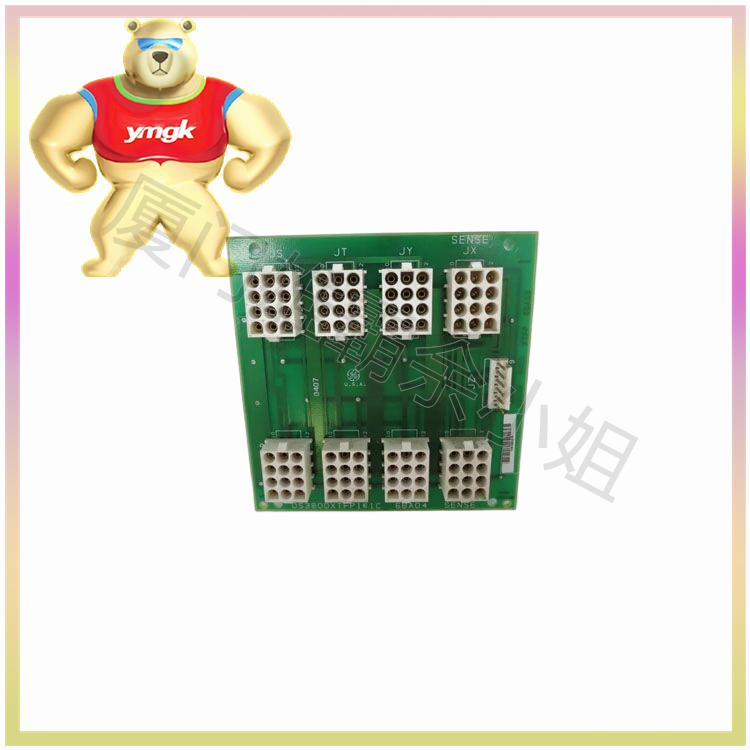

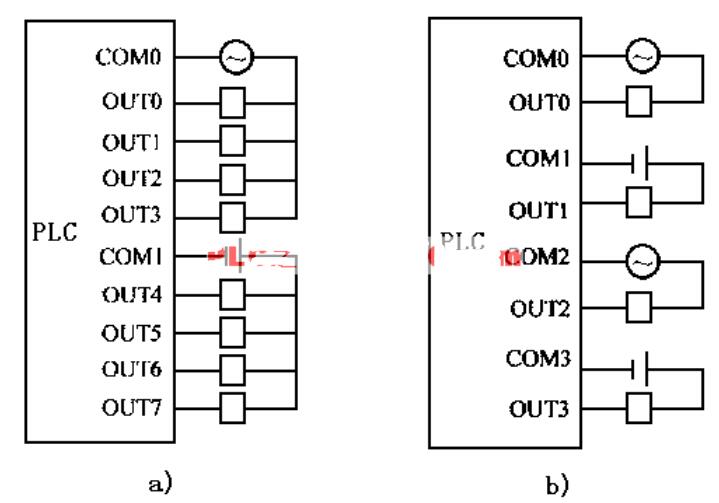

The switch input module mainly has two wiring methods: sink type and group type, as shown in the figure.

Figure Wiring method of switch input module

a) Convergence input b) Grouping input

All input points of the switch type input module share a common terminal (COM); The grouped switch input module divides the input points into several groups, each group (several input points) has a common terminal, and the groups are separated from each other. The price of grouped switch input modules is higher than that of sink type. If there is no need to separate input signals, sink type is generally selected.

3) Pay attention to the number of input points connected simultaneously

For selecting high-density input modules (such as 32 point, 48 point, etc.), it should be considered that the number of points that the module is connected to at the same time should generally not exceed 60% of the input points.

4) Input threshold level

In order to improve the reliability of the system, the size of the input threshold level must be considered. The higher the threshold level, the stronger the anti-interference ability, and the farther the transmission distance, please refer to the PLC manual for details.

- Selection of switch output module

The switch output module converts low voltage signals inside the PLC into switch signals that drive external output devices, and achieves electrical isolation between internal and external signals of the PLC. When making a choice, the following aspects should be considered:

1) Output method

The switch output module has three modes: relay output, thyristor output, and transistor output.

The price of relay output is cheap, and it can be used to drive both AC and DC loads. It has a wide range of applicable voltage sizes, small conduction voltage drop, and strong ability to withstand instantaneous overvoltage and overcurrent. However, it is a contact element with slow operating speed (when driving inductive loads, the contact operating frequency should not exceed 1HZ), short service life, and poor reliability, and can only be used in situations where frequent switching is not necessary.

For loads that frequently switch on and off, thyristor output or transistor output should be selected, as they belong to contactless components. But thyristor output can only be used for AC loads, while transistor output can only be used for DC loads.

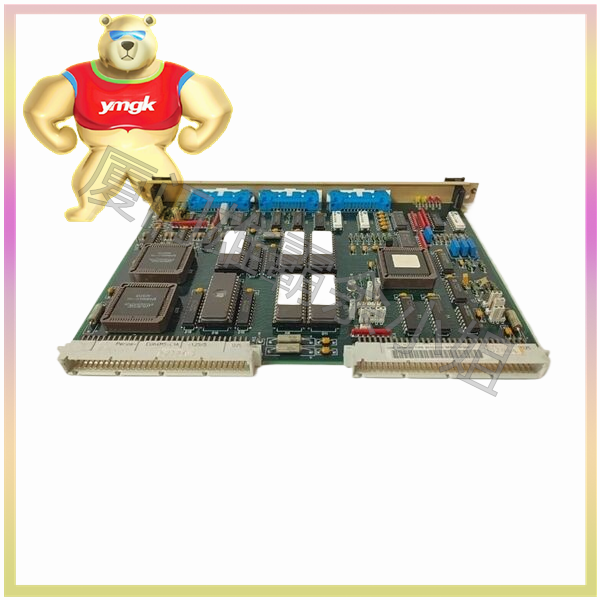

2) Output wiring method

The switch output module mainly has two wiring methods: grouped and separated, as shown in the figure.

Wiring method of switch output module

a) Group output b) Separated output

Group output refers to several output points grouped together, with a common terminal for each group. The groups are separated and can be used to drive external output devices of different power sources; Separated output means that each output point has a common terminal, and the output points are isolated from each other. The selection is mainly based on the power type and voltage level of the PLC output device. Generally, integrated PLCs have both grouped and separated outputs.

3) Driving ability

The output current (driving capability) of the switch output module must be greater than the rated current of the external output equipment of the PLC. Users should choose the output current of the output module based on the actual current size of the output device. If the current of the actual output device is large and the output module cannot be directly driven, an intermediate amplification link can be added.

4) Pay attention to the number of output points connected simultaneously

When selecting a switch output module, the number of output points that can be simultaneously connected should also be considered. The cumulative current value of simultaneously connecting output devices must be less than the current value allowed to pass through the common terminal. For example, in a 220V/2A 8-point output module, each output point can withstand a current of 2A, but the current allowed to pass through the output common terminal is not 16A (8 × 2A), usually much smaller than this value. Generally speaking, the number of points connected simultaneously should not exceed 60% of the output points of the same common terminal.

5) The maximum output current is related to factors such as load type, ambient temperature, etc

The technical specifications of the switch output module are closely related to different types of loads, especially the maximum current output. In addition, the maximum output current of thyristors will decrease with the increase of ambient temperature, which should also be noted in practical use.

(2) Selection of analog I/O module

The main function of the analog I/O module is data conversion and is connected to the internal bus of the PLC. At the same time, it also has electrical isolation function for safety. The analog input (A/D) module converts continuous analog signals generated by sensors on site into digital signals that are acceptable within the PLC; The analog output (D/A) module converts the digital signals inside the PLC into analog signals for output.

The typical range of analog I/O modules is -10V~+10V, 0~+10V, 4~20mA, etc., which can be selected according to actual needs, while also considering factors such as resolution and conversion accuracy.

Some PLC manufacturers also provide special analog input modules that can be used to directly receive low-level signals (such as RTD, thermocouple, etc.).

(3) Selection of Special Function Modules

At present, PLC manufacturers have successively launched some I/O modules with special functions, and some have also launched intelligent I/O modules with built-in CPUs, such as high-speed counters, cam simulators, position control modules, PID control modules, communication modules, etc.