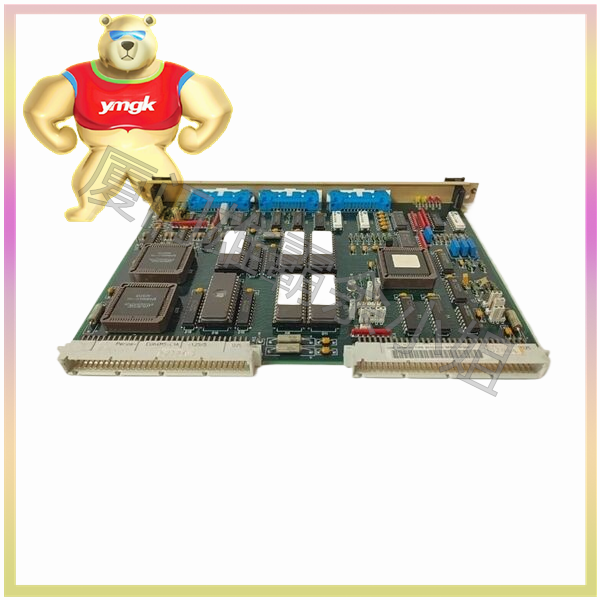

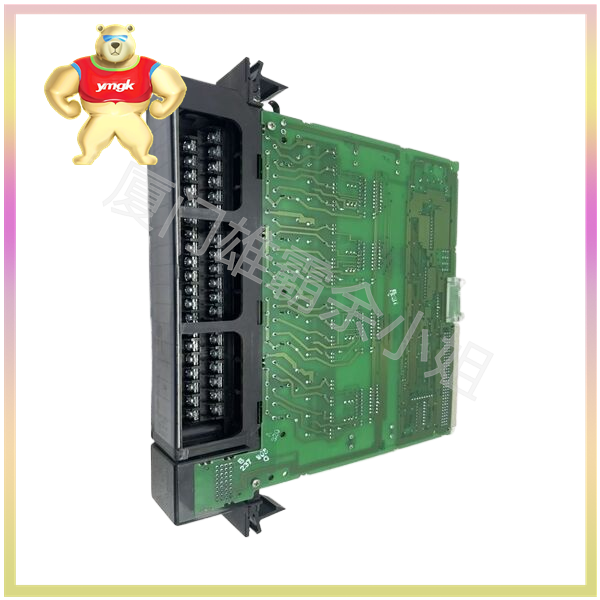

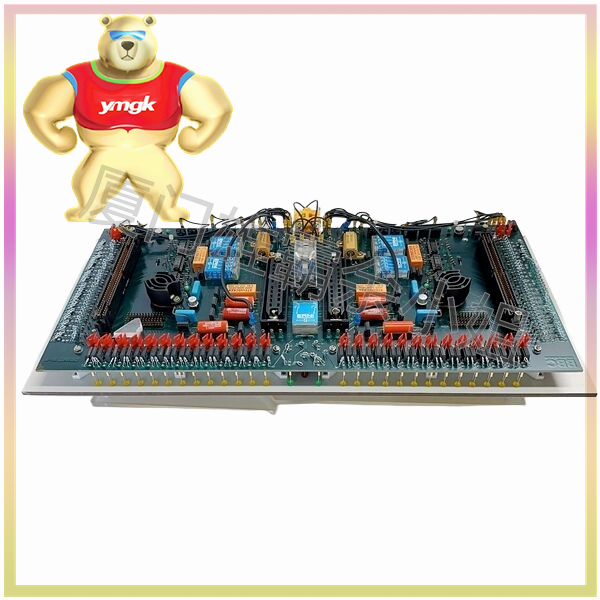

Control relay is an automatic electrical device suitable for long-distance connection and disconnection of small capacity AC and DC control circuits, and is used for control, protection, and signal conversion in power drive systems.

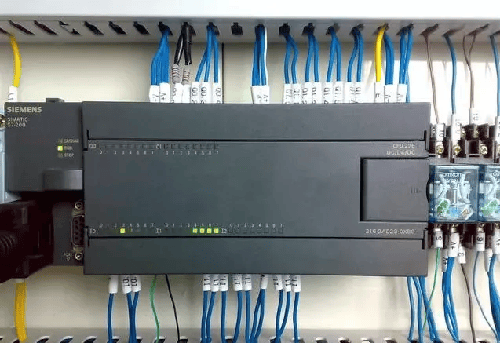

PLC is a digital arithmetic controller with a microprocessor used for automation control, which can load control instructions into memory for storage and execution at any time.

https://www2.elecfans.com/www/delivery/afr.php?target=_blank&cb=0.20939095342506509&zoneid=30&prefer=https%3A%2F%2Fwww.elecfans.com%2Fd%2F4011711.html&source_id=new -middle-berry

difference:

- Logical control mode

(1) Relay control: using hardware wiring, combining the series or parallel connection of relay mechanical contacts to form control logic, with multiple and complex connections, large volume, and high power consumption. The limited number of contacts in relays restricts the flexibility and scalability of the system.

(2) PLC control: stored in memory as a program, changing the program can change the logic; It has few connections, small size, low power consumption, and the theoretical number of contacts for each soft relay is unlimited, so its flexibility and scalability are very good.

- Sequential control method

(1) Relay control: using the hysteresis action of time relays to achieve sequential control over time; The internal mechanical structure is susceptible to changes in environmental temperature and humidity, resulting in low timing accuracy.

(2) PLC control: a timer composed of semiconductor circuits and clock pulses generated by crystal oscillators, with high timing accuracy; It can be set regularly in the program as needed, unaffected by the environment, and has great flexibility.

- Control speed

(1) Relay control: relying on the suction action of mechanical contacts to complete control tasks, with low operating frequency and slow speed.

(2) PLC control: using program instructions to control semiconductor circuits to achieve stable, reliable, and fast operation speed.

- Flexibility and scalability

(1) Relay control: Due to the limited number of electrical equipment contacts and complex wiring, the flexibility and scalability of the system are poor.

(2) PLC control: with dedicated input and output modules, few connections, good flexibility and scalability.

- Counting function

(1) Relay control: does not have counting function.

(2) PLC control: There are specific counters inside the PLC that can achieve step-by-step control of production equipment.

- Reliability and maintainability

(1) Relay control: The contacts will generate arcs when opening and closing, causing mechanical wear, short service life, poor operational reliability, and difficult maintenance.

(2) PLC control: The internal switch actions are all completed by contactless semiconductor circuits, with small size, long lifespan, high reliability, and the ability to display the execution status of monitoring and control programs at any time, making it convenient for on-site debugging and maintenance.

Summary:

Therefore, in practical applications, whether we choose to use control relays or PLCs depends on the specific control requirements and application scenarios. Control relays are suitable for simple control tasks, such as switch control of a single device or simple logic control. They are inexpensive, easy to maintain and replace, and have stable and reliable performance in some simple control scenarios.

However, if the control task is complex, involving multiple inputs and outputs, requiring logical judgment, timing control, and other functions, then using a PLC may be more suitable. PLC has strong flexibility and scalability, and can write complex control programs to achieve more precise and automated control. Meanwhile, PLC also has high stability and reliability, suitable for long-term stable operation in industrial environments.

In summary, PLC is currently commonly used as an industrial logic controller in industrial environments, and is generally better used in combination with relays, upper computers, and electrical equipment, with a wider range of applications.