The Application Principle of PLC in Robot Control

PLC is a digital operational electronic system designed specifically for industrial environments. It uses programmable memory to store instructions for executing logical operations, sequential control, timing, counting, and arithmetic operations, and controls various types of mechanical equipment or production processes through digital or analog inputs/outputs. In robot control, PLC receives input signals from robot sensors, performs logical operations and judgments according to preset programs, and then outputs control signals to the robot’s actuator to achieve control of the robot.

3、 Steps to Control Robots with PLC

Determine control requirements

Before using PLC to control a robot, it is necessary to first clarify the control requirements of the robot, including its motion trajectory, speed, acceleration, positioning accuracy, etc. These requirements will directly affect the writing and configuration of PLC programs.

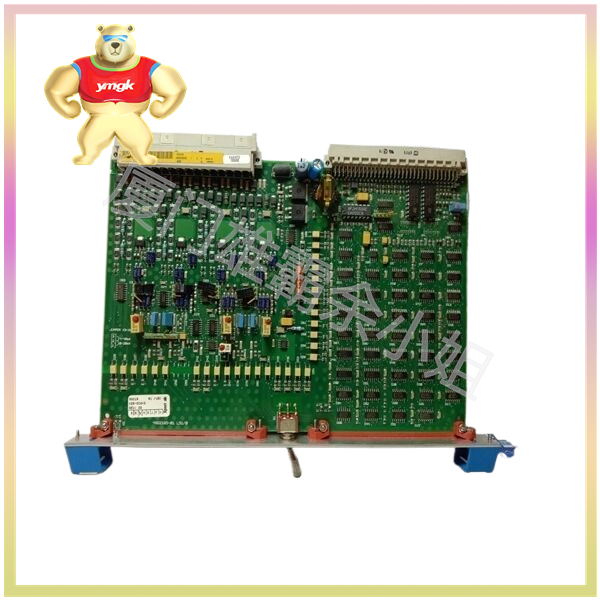

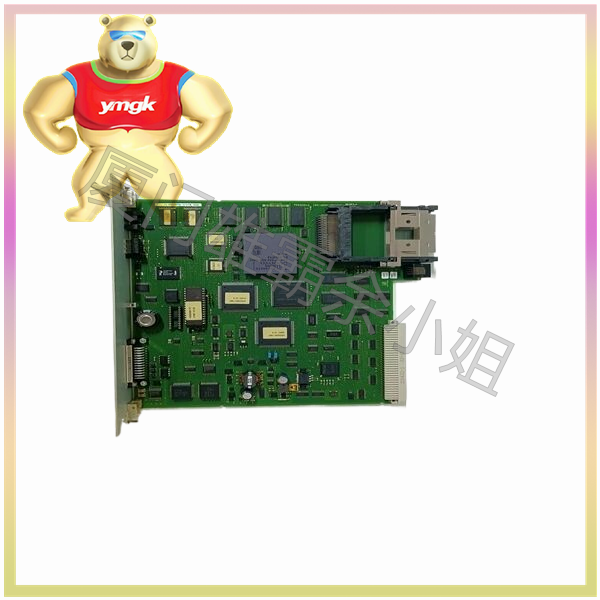

Choose the appropriate PLC model

Select the appropriate PLC model based on the control requirements of the robot. When choosing, it is necessary to consider factors such as the processing capacity, input/output points, and communication interfaces of the PLC to ensure that it can meet the control requirements of the robot.

Write PLC program

According to the control requirements of the robot, use PLC programming languages (such as ladder diagrams, instruction lists, etc.) to write control programs. When writing programs, it is necessary to fully utilize the logical operations, sequential control, timing and counting functions of PLC to achieve precise control of the robot.

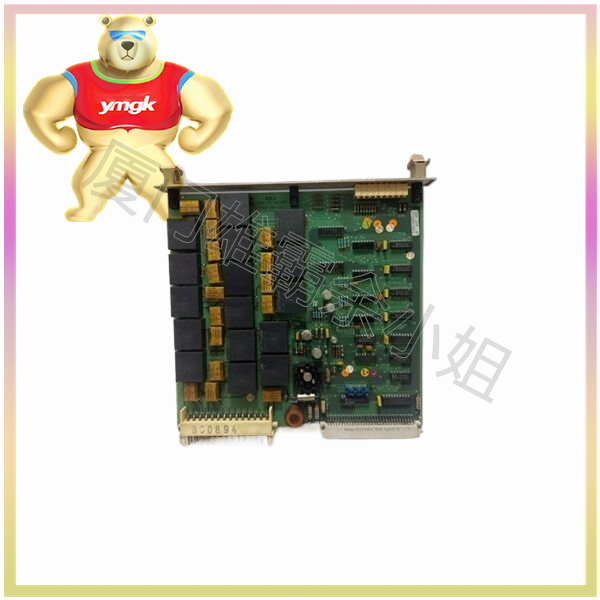

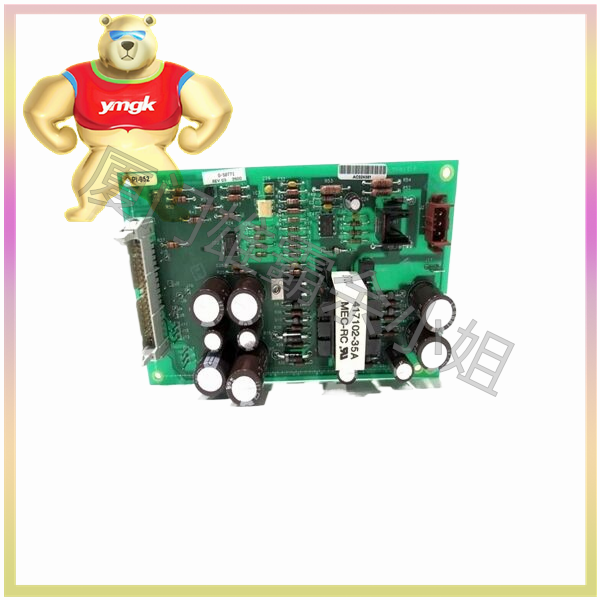

Configure input/output devices

Connect the input and output interfaces of the PLC to the sensors and actuators of the robot. When connecting, attention should be paid to signal matching and conversion to ensure that the PLC can correctly receive and send signals.

Conduct testing and debugging

After the completion of PLC programming and configuration, testing and debugging are required. By simulating the actual working environment and conditions of the robot, test the correctness and reliability of the PLC program, and make necessary adjustments and optimizations.

Realize human-computer interaction

For the convenience of operation and maintenance, PLC can interact with operators through touch screens, keyboards, and other devices. Operators can input control commands and view robot status through these devices.

4、 Practical Application Cases of PLC in Robot Control

Welding Robot Control System

In the automotive manufacturing industry, welding is a common and critical process. By using PLC to control welding robots, automated welding processes can be achieved. PLC monitors welding quality and controls welding parameters in real-time through connections with sensors and actuators, ensuring the stability of welding quality. At the same time, PLC can flexibly adjust the working mode and path of welding robots according to the needs of the production line, achieving flexible conversion between batch production and welding of multiple products.

Material handling robot control system

In the warehousing and logistics industry, material handling is an important and tedious task. By using PLC to control material handling robots, automatic handling processes can be achieved, improving handling efficiency and accuracy. By connecting with the warehouse management system, PLC can accurately obtain the location and quantity information of materials, and sort, load, and transport them according to demand. In addition, PLC can intelligently plan the handling path, avoid collisions and congestion, and improve the safety and efficiency of material handling.

5、 Summary

This article provides a detailed introduction on how to use PLC to control robots, including the application principles, control steps, and practical application cases of PLC in robot control. Through the introduction of this article, we can see that PLC plays an important role in robot control. It can not only achieve precise control of robots, but also improve their work efficiency and safety. With the continuous development of industrial automation technology, the application of PLC in robot control will become increasingly widespread, providing more reliable, efficient, and intelligent solutions for the development of robot technology.