Servo control system is a high-precision, high response speed automatic control system widely used in industrial automation, robotics, aerospace and other fields. This article will provide a detailed introduction to the composition of a servo control system, including servo motors, drivers, controllers, sensors, actuators, and their interrelationships and interactions.

servo motor

Servo motor is the core component of servo control system. It is a high-precision and high response speed motor that can achieve precise control of rotor position, speed, and acceleration. The working principle of a servo motor is to convert the input electrical signal into mechanical motion, and drive the load to move through the rotor of the motor.

There are many types of servo motors, such as DC servo motors, AC servo motors, stepper motors, etc. Among them, DC servo motors have the advantages of simple structure, convenient control, and fast response speed, but they have disadvantages such as brush wear and high maintenance costs. AC servo motors have advantages such as high efficiency, high power density, and low maintenance costs, but their control is relatively complex. Stepper motors have the advantages of simple structure, low cost, and convenient control, but their accuracy and response speed are relatively low.

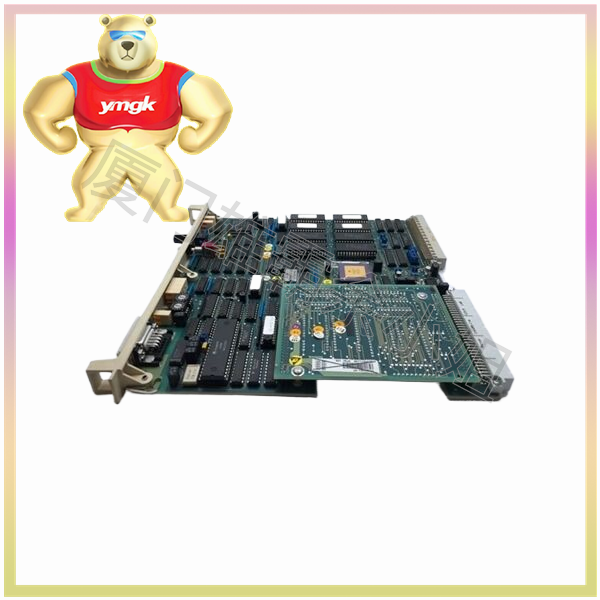

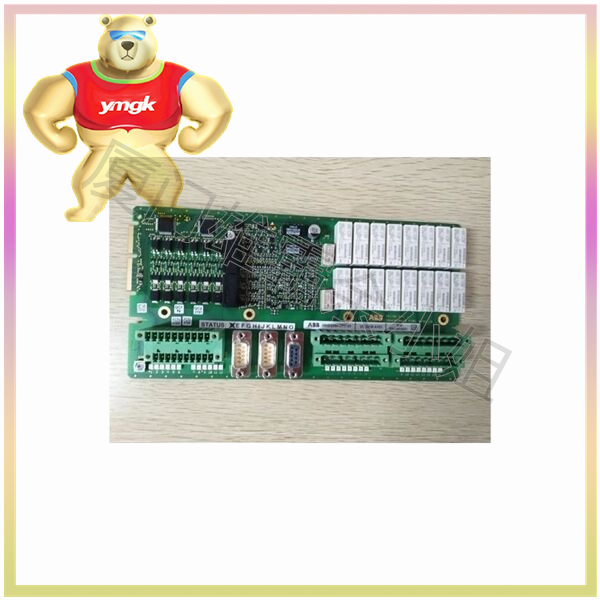

Driver

The driver is a key component in the servo control system, responsible for receiving command signals from the controller, converting electrical energy into mechanical energy, and driving the servo motor to move. There are many types of drivers, such as pulse drivers, analog drivers, digital drivers, etc.

Pulse driver is the most common type of driver, which controls the speed and direction of the motor by receiving pulse signals. The advantages of pulse drivers are simple control and low cost, but their accuracy and response speed are relatively low.

The analog driver controls the speed and direction of the motor by receiving analog signals, which has high accuracy and response speed, but relatively high cost.

Digital drivers use digital signal processing technology, which has advantages such as high precision, high response speed, and high reliability, but the cost is relatively high.

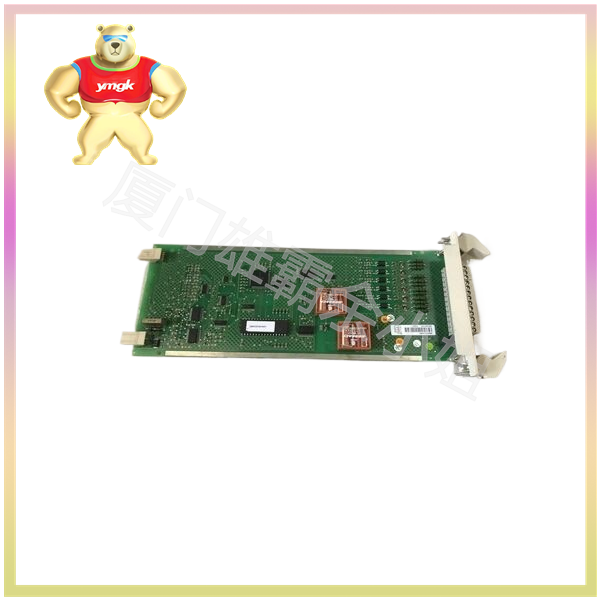

controller

The controller is the brain of the servo control system, responsible for receiving feedback signals from sensors, generating control instructions based on the system’s control algorithm, and controlling the motion of the servo motor through the driver. There are many types of controllers, such as PLC, microcontroller, industrial computer, etc.

PLC (Programmable Logic Controller) is a widely used controller in the field of industrial automation, with advantages such as simple programming, high reliability, and good scalability.

A microcontroller is a small, low-cost, and powerful microcontroller suitable for simple servo control systems.

Industrial computer is a high-performance and highly reliable controller suitable for complex servo control systems.

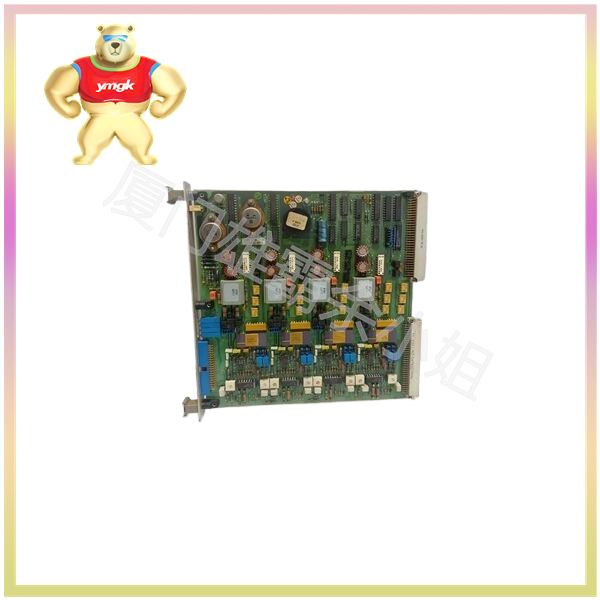

sensor

Sensors are the perception organs of servo control systems, responsible for detecting the motion status of the system and feeding back the detected information to the controller. There are many types of sensors, such as encoders, photoelectric sensors, Hall sensors, etc.

Encoder is a high-precision position sensor that can detect the rotor position and speed of a motor. There are many types of encoders, such as incremental encoders, absolute encoders, etc.

The incremental encoder calculates the position and speed of the rotor by detecting the rotation direction and number of steps of the motor rotor. The advantages of incremental encoders are simple structure and low cost, but there are accumulated errors.

The absolute encoder detects the absolute position of the motor rotor and calculates the position and speed of the rotor. The advantages of absolute encoders are high accuracy and no cumulative error, but the cost is relatively high.

Other types of sensors such as photoelectric sensors and Hall sensors can be used to detect other states of the system, such as load force, temperature, etc.

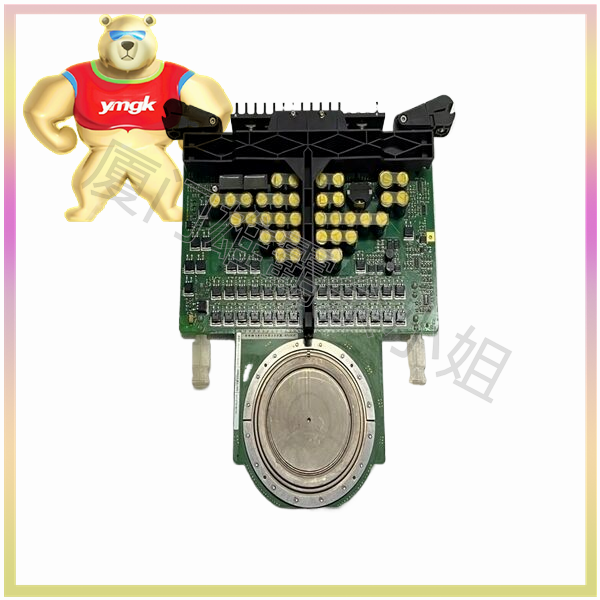

Executing Agency

The actuator is the executing component of the servo control system, responsible for converting the motion of the motor into actual mechanical motion and achieving control of the load. There are many types of actuators, such as lead screws, gears, hydraulic cylinders, etc.

Screw is a common actuator that drives the screw to rotate through a motor, achieving linear motion of the load. The advantages of screw are simple structure and high precision, but there are disadvantages such as wear and low efficiency.

Gear is a common transmission mechanism that drives gears to rotate through a motor, achieving rotational motion of the load. The advantages of gears are simple structure and high efficiency, but they have disadvantages such as noise and wear.

Hydraulic cylinder is a common actuator that drives a hydraulic pump through an electric motor to achieve linear or rotational motion of the load. The advantages of hydraulic cylinders are high torque and fast response speed, but they have disadvantages such as leakage and high maintenance costs.

systems software

System software is an important component of servo control systems, responsible for implementing control algorithms, data processing, human-computer interaction, and other functions of the system. There are many types of system software, such as embedded software, PC software, etc.

Embedded software is a type of software that runs on a controller and has the advantages of high real-time performance, high reliability, and low cost. The development of embedded software requires consideration of hardware resource limitations and the use of specific programming languages and development tools.

PC software is a type of software that runs on industrial computers and has the advantages of powerful functionality, easy development, and scalability. The development of PC software needs to consider the compatibility of the operating system, using universal programming languages and development tools.

System debugging and maintenance

The debugging and maintenance of servo control system are important links to ensure the normal operation of the system. Debugging includes parameter settings, performance testing, fault diagnosis, etc., which need to be adjusted according to the actual situation of the system.