Industrial control has evolved from early on-site control and centralized control to current distributed control (DCS). In the past 20 years, the process industry has invested heavily in DCS systems and related instrumentation, and the application results of DCS systems have been recognized by users. The 4-20mA signal is the most essential characteristic of the interconnection between DCS systems and field equipment, which is a major advancement in the development of control systems and instrumentation devices.

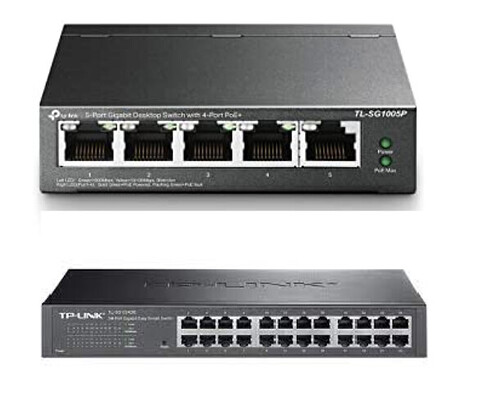

However, digitalization and networking have become the main directions for the development of control networks today. People have realized that traditional analog signals can only provide raw measurement and control information, and the ability of smart transmitters to add information on top of 4-20mA signals is limited by their low communication rate. Therefore, digitizing and networking the mechanism of the entire process control system should be an inevitable trend in its development.

Fieldbus provides a fully digital, bidirectional, multi node communication link between intelligent field devices and automation systems. The emergence of fieldbus has promoted the digitization and networking of field devices, and made the functions of field control more powerful. This improvement brings openness to the process control system, making it a control network with comprehensive capabilities of measurement, control, execution, and process diagnosis.

- The impact of fieldbus on traditional DCS

The impact of fieldbus on traditional DCS comes from its fundamentally superior technical features compared to DCS systems. According to the definitions of the International Electrotechnical Commission (IEC) and the Fieldbus Foundation (FF), fieldbus technology has the following five main characteristics:

① Digital signals completely replace 4-20mA analog signals;

② Ensure that basic process control, alarm, and calculation functions are fully distributed on-site;

③ Add non control information to the device, such as self diagnostic information, configuration information, and compensation information;

④ Realize the unity of on-site management and control;

⑤ Truly achieve system openness and interoperability.

Fieldbus technology is not only a communication technology, but also integrates the essence of intelligent instruments, computer networks, and Open Systems Interconnection (OSI) technologies. All these characteristics make fieldbus control systems (FCS) based on fieldbus technology have significant advantages over traditional DCS systems:

① The system structure is greatly simplified, and the cost is significantly reduced;

② Enhanced autonomy of on-site equipment and comprehensive improvement of system performance;

③ Improved the reliability and accuracy of signal transmission;

④ Truly realizing a fully decentralized and digitized control network;

⑤ Users always have system integration rights.

These advantages can be verified by comparing the network structures of DCS and fieldbus systems.

- The integration of fieldbus into DCS systems is the current trend in the development of control networks

Although users welcome the structural improvements of the control system, they do not wish to make significant changes to their existing instrument system.

At present, in the early stages of fieldbus development, most users prefer to gradually add and replace their existing instrument systems; On the other hand, the disappearance or complete replacement of DCS systems and their instruments is also unreasonable in terms of cost or manpower. The most feasible solution at this stage is to consider how to make the fieldbus and traditional DCS system work together as much as possible. This integrated solution can obtain flexible system configuration, which is suitable for a wider range of practical applications.

- Integration of fieldbus on DCS system I/O bus

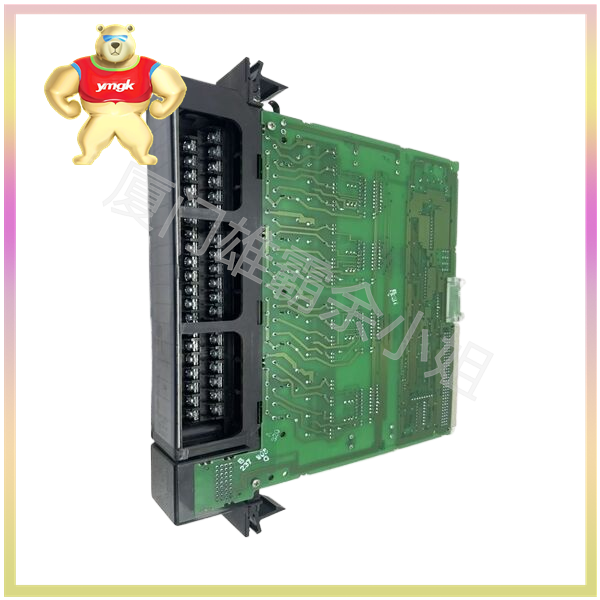

In the DCS architecture, it can be roughly divided into three layers from top to bottom: management layer, monitoring and operation layer, and I/O measurement and control layer. On the I/O bus of the I/O measurement and control layer, there are DCS controllers and various I/O cards hanging. The I/O cards are used to connect on-site 4-20mA devices, discrete quantities or PIC signals, and the DCS controller is responsible for on-site control.

The key to integrating fieldbus on the I/O bus of DCS system is to hang a fieldbus interface card on the I/O bus of DCS, so as to map the data information in the fieldbus system to the corresponding data information on the original DCS I/O bus, such as basic measurement values, alarm values or process setting values, so that the information from the fieldbus seen by the DCS controller is like coming from a traditional DCS equipment card. This achieves the integration of fieldbus technology on the I/O bus.

This solution is mainly suitable for small-scale applications where DCS systems have already been installed and are running stably, and fieldbus is introduced into the system for the first time; This solution can also be applied to PLC systems.

The advantage of this solution is that the structure is relatively simple, but the disadvantage is that the integration scale is limited by the fieldbus interface card.

The DeltaV DCS system launched by Fisher Rosemount adopts this integration solution. The DeltaV system has specifically developed and designed an interface card for this function in its I/O cards – the fieldbus H1 communication module (31.25kbit/s), which successfully integrates fieldbus technology into the DeltaV system and can be connected to fieldbus instruments, greatly saving installation, operation, and maintenance costs. The same controller is compatible with H1 and traditional I/O modules, which is beneficial for traditional control modules. Transition and transformation from fieldbus control mode.

In the field bus H1 communication module of the DeltaV system, there is a specific driver used to map the data information of the field bus system to the corresponding information on the I/O bus.

- Integration of Fieldbus into DCS System Network Layer

In addition to integration solutions on the I/O bus, fieldbus systems can also be integrated on a higher layer – the DCS network layer. In this scheme, the fieldbus interface card is not hung on the I/O bus of the DCS, but on the upper LAN of the DCS.

In this scheme, fieldbus control execution information, measurement, and control functions of field instruments can all be browsed and modified at the DCS operation station. Its advantage is that some control and calculation functions that originally had to be completed by the DCS main computer can now be delegated to on-site instruments for implementation, and relevant parameters or data information can be obtained on the DCS operator interface; Another advantage of it is that it does not require any modifications to the DCS control station, resulting in minimal impact on the existing system.

- Fieldbus is integrated in parallel with DCS system through gateway

If a DCS system and a fieldbus system are running in parallel in a factory, a gateway can also be used to connect the two and install the gateway to complete the information transmission between the DCS system and the fieldbus high-speed network.

In this structure, information from the DCS system can be obtained and displayed on the new operator interface. By using a throwing bridge, a large number of H1 low-speed buses can be installed. The fieldbus interface unit can provide functions such as control coordination, alarm management, and short-term trend collection.

The parallel integration of fieldbus and DCS completes the integration and unification of the control system and information system of the entire factory, and can achieve interconnection between Infranet and Inernet through a web server. The advantage of this approach is that it enriches the information content of the network, making it easier to leverage the comprehensive advantages of data information and control information; In addition, in this integration scheme, the fieldbus system and the DCS system integrated through the gateway are independent of each other.

- Conclusion

In summary, we believe that fieldbus systems will be widely applied in process industry control. By making necessary modifications to the process control system and introducing fieldbus technology into DCS, it will bring significant benefits to users; On the other hand, even though most continuous control loops will be completed by fieldbus systems, DCS systems will still play an important role in many control scenarios with high real-time requirements. At present, the coexistence of fieldbus and DCS system will provide users with more choices to achieve a more reasonable control system.