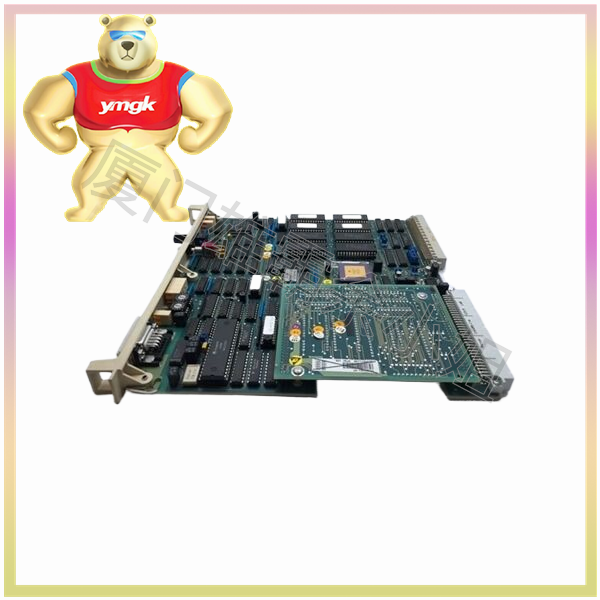

1、 Overview of PLC input devices

The input devices of PLC are the bridge for interaction between PLC and the external world. They convert physical signals from the external environment (such as switch signals, analog signals, etc.) into digital signals that PLC can recognize. After being processed by PLC, these digital signals can control the output devices to perform corresponding actions, thereby achieving automation control of the production process.

2、 Classification of PLC input devices

There are various types of input devices for PLC, which can be classified into the following categories based on their functions and signal types:

Switching input device

Switching input devices are one of the most common PLC input devices, which indicate the presence or absence of signals through the on/off status of switches. This type of equipment mainly includes:

Button switch: Button switch is a commonly used input device for PLC, used to manually send control signals. They change the on/off state of the circuit by pushing the transmission mechanism to connect or disconnect the moving and stationary contacts. In electrical automatic control circuits, button switches are used to achieve functions such as starting and stopping the system.

Travel switch: A travel switch is a device that uses the collision of mechanical moving parts to issue control commands. It is commonly used in scenarios such as limit protection and automatic reciprocating motion of mobile mechanical equipment. The travel switch is a contact switch, which is prone to malfunction when operated frequently, resulting in relatively low operational reliability.

Proximity switch: A proximity switch is a switch that can detect the position of a target object without direct contact with it. It works based on principles such as electromagnetic induction and photoelectric effect, and has advantages such as fast response speed and long detection distance. Proximity switches are typically used to detect parameters such as position and velocity of metal objects.

Transfer switch: A transfer switch is a switch device with multiple contact combinations that can achieve multi-channel conversion and switching of circuits. In PLC control systems, toggle switches are commonly used to select different control programs or parameter settings.

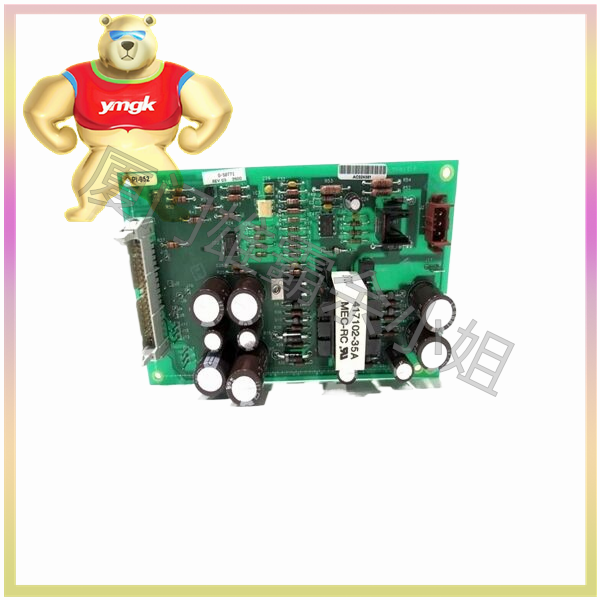

Analog input device

Analog input devices are used to convert continuously changing physical quantities (such as temperature, pressure, flow rate, etc.) into digital signals that PLC can recognize. This type of equipment mainly includes:

Sensor: A sensor is a device that converts non electric signals into electric signals. In PLC control systems, sensors are used to detect various physical quantities and convert them into digital signals for input to the PLC. Common sensors include temperature sensors, pressure sensors, flow sensors, etc.

Transmitter: A transmitter is a device that amplifies, converts, and outputs the weak signal output by a sensor. It can convert the output signal of the sensor into standard electrical signals (such as 4-20mA, 0-10V, etc.) for PLC to collect and process.

Other input devices

In addition to the two common input devices mentioned above, there are also other types of input devices widely used in PLC control systems, such as dip switches, barcode readers, etc. These devices can be selected and configured according to specific application scenarios.

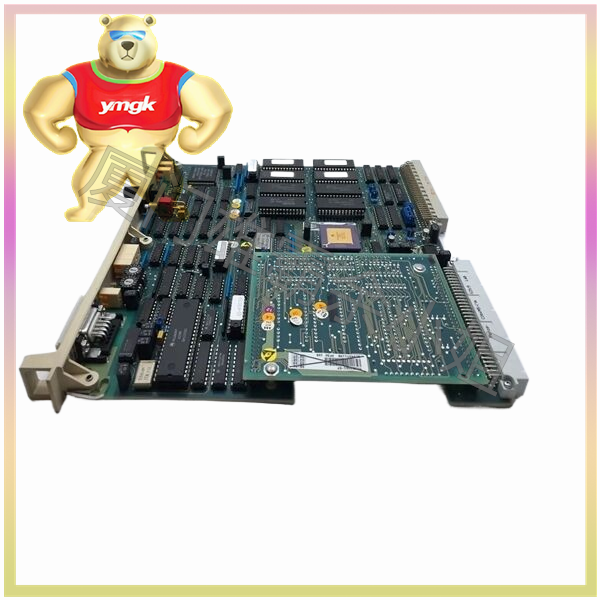

3、 Characteristics of PLC input devices

The input devices of PLC have the following characteristics:

Strong universality: The input devices of PLC can adapt to different signal types and signal ranges, with high universality and flexibility.

High reliability: The input devices of PLCs usually use high-quality electronic components and manufacturing processes, which have high reliability and stability.

Easy to maintain: The input devices of PLCs are usually designed modularly, making them easy to replace and maintain. At the same time, the input devices of PLC also have self diagnostic functions, which can timely detect and report fault information.

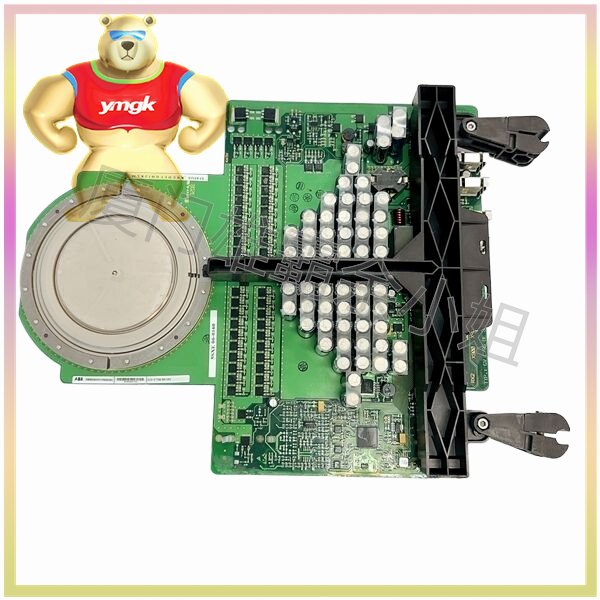

4、 Summary

The input device of PLC is one of the key links to achieve interaction between PLC and the external world. They achieve automated control of the production process by receiving external signals and converting them into digital signals that can be recognized by PLC. This article provides a detailed introduction to the classification, characteristics, and application scenarios of PLC input devices, and elaborates on them in conjunction with relevant numbers and information from the reference article. In practical applications, we need to select suitable input devices based on specific application scenarios and requirements, and configure and optimize them reasonably to ensure the normal operation and efficient work of PLC control systems.