- The two have different structures/working principles

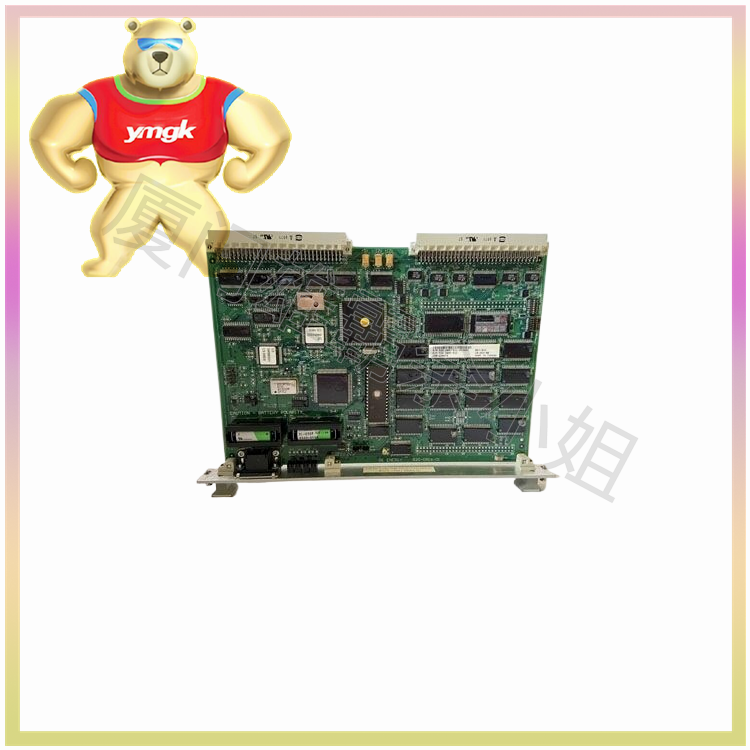

A mechanical relay is composed of an iron core, a coil, and contacts. When the coil is energized, the current in the coil generates a magnetic field, causing the contacts to move, thus completing the working principle of a mechanical relay.

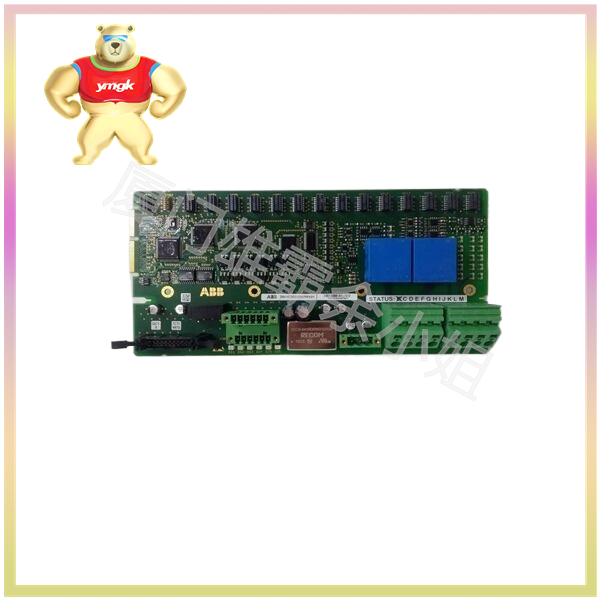

Solid state relays are entirely composed of electronic components, with typical components including optocouplers. DC loads use MOS transistors as power switching devices, while AC loads use thyristors as power switching devices.

- The contact forms of the two are different

The contacts of mechanical relays are mechanical and generate electric sparks, also known as arcs, when breaking high currents. Arc suppression is an industry challenge as contacts can corrode and shorten their service life when working in an arc environment for a long time. Therefore, mechanical relays are labeled with a service life.

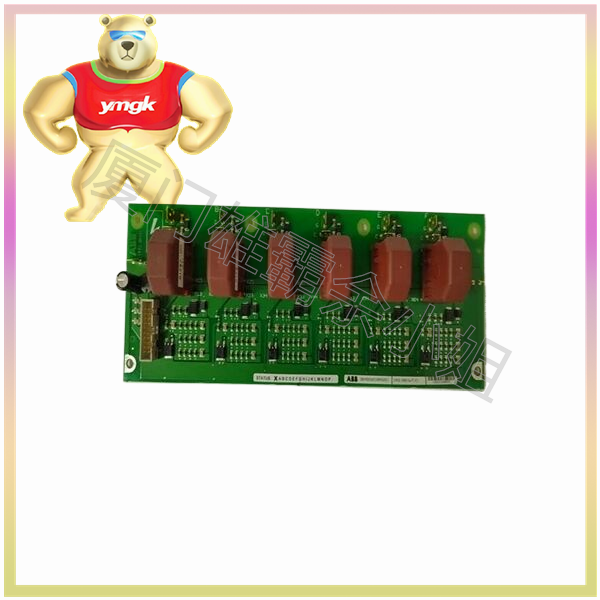

The contacts of solid-state relays are electronic, such as MOS transistors or thyristors, which eliminates the influence of arcing, so there is almost no limit to their lifespan under reasonable use. However, excessive current in electronic devices requires the attachment of heat sinks, and the larger the current, the larger the heat sinks needed.

- The switch noise is different

Friends who have used mechanical relays know that there is a sound of contact movement when the relay is activated, and the louder the contact, the louder the sound. In contrast, electronic contacts of solid-state relays have no sound during operation, making them relatively quieter. In addition, mechanical contacts have bouncing/shaking problems during operation, resulting in uneven current waveforms, while electronic contacts are much better in this situation.