Structural characteristics of DC relays

DC relays do not generate reactance when DC is applied, so the coil diameter of DC relays is relatively thin, mainly to increase internal resistance and prevent approximate short circuit phenomenon. Due to the large amount of heat generated during operation, the relay is made higher and longer, mainly for good heat dissipation effect.

Working principle of DC relay

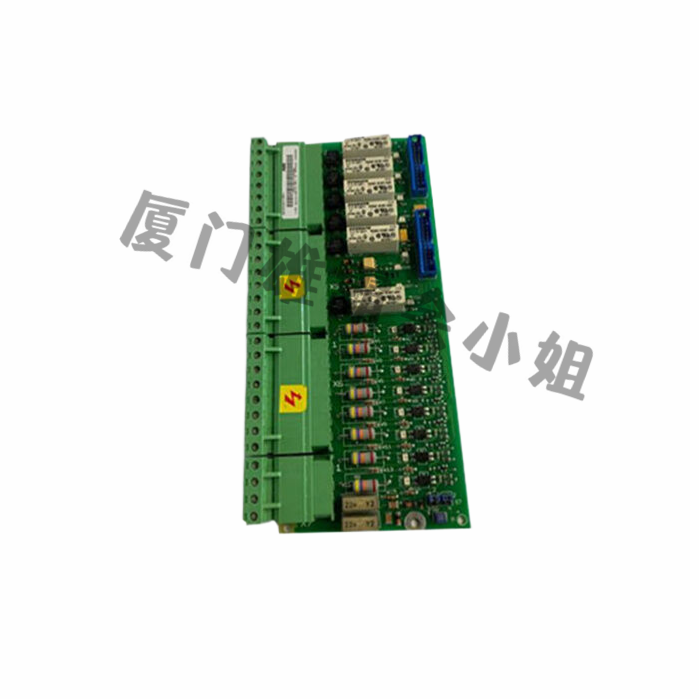

A DC relay consists of a coil, an iron core, and several sets of normally open and normally closed contacts.

When the relay coil is connected to the rated voltage DC, the coil generates a magnetic field, attracting the iron core to move, and the normally open contact connected to the iron core closes, while the normally closed contact opens.

When the relay coil loses power, the coil loses its magnetic field, and the attracted iron core returns to its original position under the action of the spring. The normally open contact connected to the iron core is disconnected, and at the same time, the normally closed contact is closed.

Relays achieve logical control of equipment by controlling the on/off of coils, enabling the connection and disconnection of contacts.

2、 Communication relay

The working principle of AC electromagnetic relay is basically the same as that of DC electromagnetic relay. AC electromagnetic relay works in AC circuit. When AC current passes through the coil, alternating magnetic flux is generated in the iron core. Since the traction force (electromagnetic attraction) is proportional to the square of the magnetic flux φ, when the current changes direction, the traction force does not change direction and always attracts the armature towards the iron core in one direction.

However, due to the alternating current generating alternating magnetic flux in the iron core, AC electromagnetic relays have their unique characteristics and structure.

Structure of communication relay

The coil of an AC relay is relatively short and the wire diameter is relatively thick, mainly because when AC power is applied to the coil, the reactance is large. A thicker wire diameter can reduce internal resistance and heat generation. In addition, when AC power passes through zero, the electromagnetic force of the coil will decrease, resulting in weak attraction and vibration. Therefore, a short-circuit ring is added to the magnetic attraction surface. When the magnetic field changes, eddy currents are formed in the short-circuit ring, which in turn forms an electromagnetic force in the opposite direction of the magnetic field change, lagging behind the magnetic field change and allowing the electromagnet to be well attracted.

Characteristics: (Difference from DC Relay)

In addition, DC electromagnetic relays only have a back electromotive force when the power is turned on or off. In a stable state, the current passing through the coil is determined only by the resistance, while AC electromagnetic relays, even in a stable state, still have a back electromotive force. Therefore, the current of AC relays is mainly determined not by the resistance, but by the inductance of the coil. This indicates that when calculating the circuit of AC relays, the inductance of the coil must be considered. The coil current of AC electromagnetic relays is determined by the reactance (inductance) of the coil.

Due to the fact that the current passed through the AC electromagnetic relay is a variable alternating current, the magnetic flux in its magnetic circuit also changes alternately (following a sinusoidal pattern rather than a linear pattern). The suction force acting on the armature varies between 0 and the maximum value, so the suction force of the AC electromagnetic relay is pulsating, with a frequency of twice the AC frequency. This pulsating suction force will cause the armature to vibrate, so measures should be taken structurally to eliminate vibration and affect the life of the relay.

Due to the alternating magnetic flux generated by the AC power supply passing through the iron core, eddy currents are generated in the iron core. The magnetic field generated by the eddy currents is opposite in direction to the original magnetic flux, causing some of the magnetic flux to become leakage flux and be lost, resulting in magnetic losses. In order to reduce these losses, the iron core of AC electromagnetic relays is generally made of silicon steel sheets stacked to reduce magnetic and eddy current losses.