- Motor starter

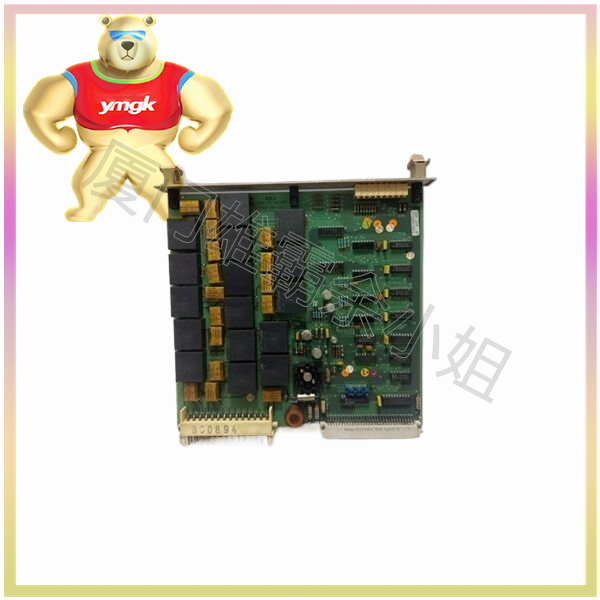

Small motors can be started by connecting a switch or circuit breaker to a power source, while large motors require a special switching unit called a motor starter or motor contactor. When starting, the DOL starter will directly connect the motor to the power source. A voltage reducing starter, Y – Δ switching starter, or soft starter will connect the power supply to the motor through a voltage reducing circuit, and then the voltage will gradually rise or rise in sections. A smaller power motor starter is a manually operated switch, while larger motors that require remote or automatic control applications typically use magnetic contactors. Medium voltage power supplies (approximately several kilovolts) use circuit breakers as switching elements.

The motor starter with direct online (DOL) will apply all the line voltage to the motor end, which is the simplest motor starter. The starter that starts directly online can also include protective components. Small power online direct start starters are manually operated, while high-power starters use electromechanical contactors (relays) to switch the motor circuit. There are also online direct start starters that use solid-state electronics.

If the high inrush current during motor start-up does not cause excessive voltage drop in the power supply, an online direct starting starter will be used. The maximum motor power that the starter can cooperate with will also be limited by the power supply’s capacity. For example, some rural power equipment may require motors with a power greater than 10kW to use a reduced voltage motor starter.

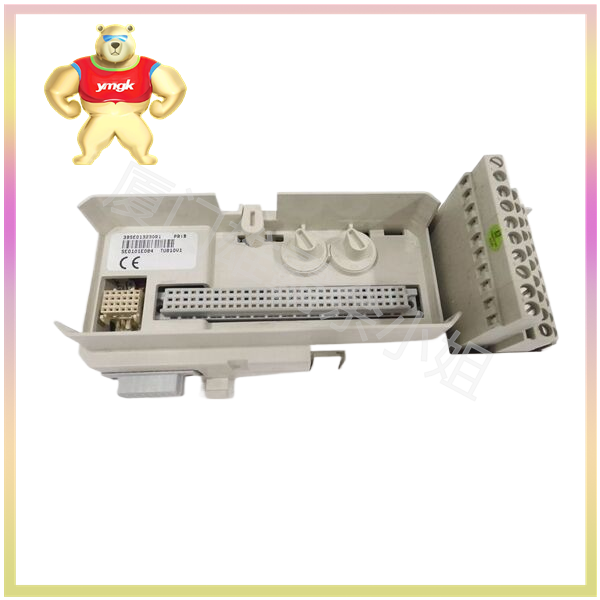

- Voltage reducing starter

Two or more contactors can be used to provide lower voltage during motor start-up. By using an autotransformer or series inductor, a lower voltage can be input at the terminals during motor start-up to reduce starting torque and inrush current. When the motor speed reaches a certain proportion of the rated speed, the starter automatically switches the motor terminals to normal voltage input. Because autotransformers and series inductors only have a heavy starting current flowing during startup, which may only take a few seconds, their ratings will be lower than those under continuous use with the same current. The switching from lower voltage to normal voltage can be done using a timer or in conjunction with a current sensor, when the current begins to decrease. The Korndrfer autotransformer starter applied for a patent in 1908.

- Variable speed drive

Adjustable speed drive (ASD) or variable speed drive (VSD) is a device group that can adjust the working speed of mechanical loads. The speed control drive includes an electric motor, speed controller or power converter, as well as auxiliary equipment or instruments. However, generally speaking, a drive is only used to refer to a controller. Many new types of speed control drives can also perform slow starting of electric motors.

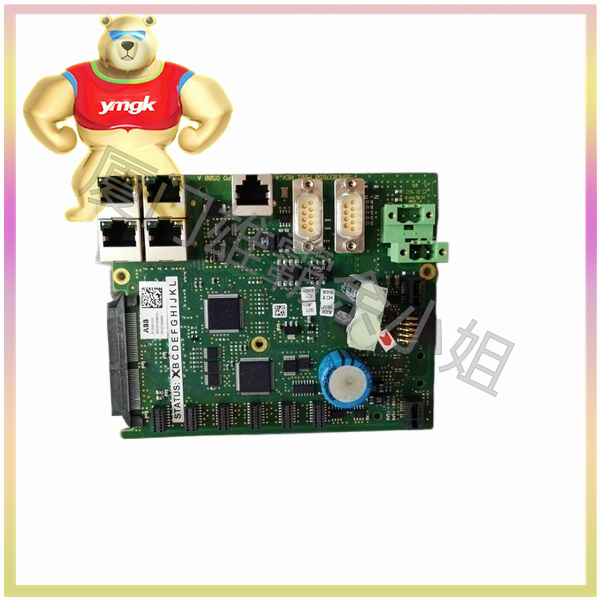

- Intelligent controller

Intelligent controllers use microprocessors to control the power components used in motor control, and can also monitor the load of the motor, matching the torque of the motor with the load. The method is to reduce the AC voltage supplied to the motor, while reducing the current and reactive power. Therefore, if the motor operates under light load conditions for a long time, the above method can measure the degree of improvement in energy efficiency, and the heat, noise, and vibration generated at this time are also reduced.