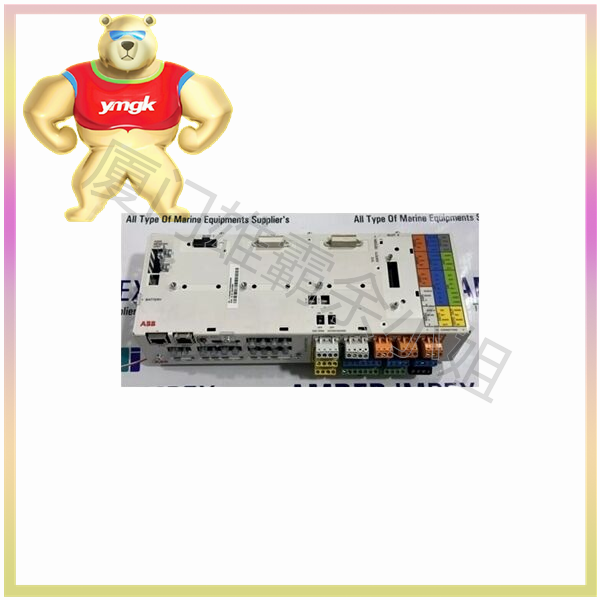

A controller is an electronic device used to control the operation of a motor. It is a central processing unit that can control the speed, steering, acceleration and other parameters of motors by receiving sensor signals and user inputs, in order to achieve motion control of robots, electric vehicles, drones and other devices.

The matching between the controller and the motor is very important. When choosing a controller, the following factors need to be considered:

- Motor type: Different types of motors require different controllers. For example, a DC motor requires a DC motor controller, while a stepper motor requires a stepper motor controller.

- Motor power: The controller needs to be able to withstand the power of the motor, otherwise it may cause damage to the controller.

- Control mode: The controller needs to support the required control modes, such as PWM, serial port, CAN, etc.

- Control accuracy: The controller needs to have sufficient control accuracy to achieve precise motion control.

- Communication protocol: The controller needs to support the required communication protocols, such as Modbus, CANopen, etc.

- Software development: The controller needs to have a corresponding software development platform so that users can write programs to achieve more advanced control functions.

Generally speaking, we need to choose controllers based on specific application scenarios and requirements. When selecting a controller, attention should be paid to the matching between the controller and the motor to ensure the stability and reliability of the system.

To better understand the matching between the controller and the motor, we can give an example. Assuming we want to control a DC motor, we need to choose a suitable DC motor controller. We can choose according to the following steps:

- Determine the power and voltage of the motor: Assuming our motor has a power of 500W and a voltage of 24V.

- Choose the appropriate controller: Based on the power and voltage of the motor, we can choose a DC motor controller that meets the requirements, such as MCU-500W-24V.

- Determine the control method: Based on the application scenario and requirements, we can choose the appropriate control method. For example, if we need to implement speed control, we can choose PWM control mode.

- Developing control programs: Based on the software development platform of the controller, we can write programs to implement the required control functions.

- Debugging and optimization: After the development of the control program is completed, we need to debug and optimize the system to ensure its stability and reliability.

In short, the matching between the controller and the motor is very important, as it directly affects the stability and reliability of the system. When selecting a controller, factors such as motor type, power, control mode, control accuracy, communication protocol, and software development need to be considered to ensure a good match between the controller and the motor. Meanwhile, debugging and optimization are also required to ensure the stability and reliability of the system.