A driver, also known as a driving device or driving mechanism, is a component in mechanical equipment used to transmit and convert energy, control motion, and achieve specific functions. Drivers play a crucial role in various mechanical equipment and systems, with a wide variety of types and diverse functions. This article will provide a detailed introduction to the role, classification, working principle, and applications of drivers in different fields.

1、 The function of the driver

- Energy transfer: One of the main functions of a driver is to convert energy from one form to another in order to achieve the operation of mechanical equipment. For example, electric motors convert electrical energy into mechanical energy, while hydraulic pumps convert hydraulic pressure energy into mechanical energy.

- Control motion: Drivers can control the speed, direction, and acceleration of mechanical equipment to meet the needs of production and work. For example, servo motors can accurately control the motion trajectory and speed of robotic arms.

- Implement specific functions: Drivers can achieve specific functions according to different needs, such as positioning, synchronization, speed regulation, etc. For example, stepper motors can achieve precise positioning control, while synchronous motors can achieve synchronous operation of multiple devices.

- Equipment protection: Drivers can protect mechanical equipment from damage through measures such as overload protection and short circuit protection. For example, overload protection devices can automatically cut off power when the drive is subjected to excessive load, preventing equipment damage.

- Improve efficiency: Drivers can improve the operational efficiency of mechanical equipment and reduce energy consumption. For example, a variable frequency drive can automatically adjust the operating frequency of the motor according to changes in load, achieving energy conservation and consumption reduction.

2、 Classification of Drivers

- Classified by energy conversion method: Drivers can be divided into electric drivers, hydraulic drivers, pneumatic drivers, etc.

- Classified by motion mode: Drivers can be divided into linear motion drivers, rotary motion drivers, swing motion drivers, etc.

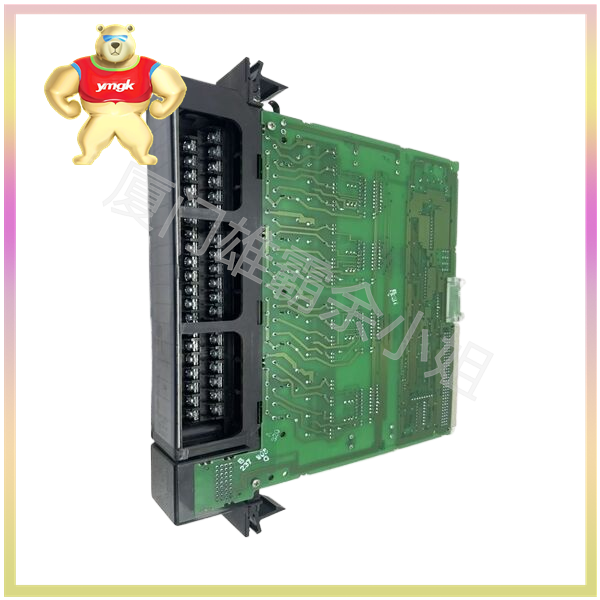

- Classified by control method: Drivers can be divided into open-loop drivers, closed-loop drivers, semi closed-loop drivers, etc.

- Classified by function: Drivers can be divided into positioning drivers, speed regulating drivers, synchronous drivers, etc.

3、 The working principle of the driver

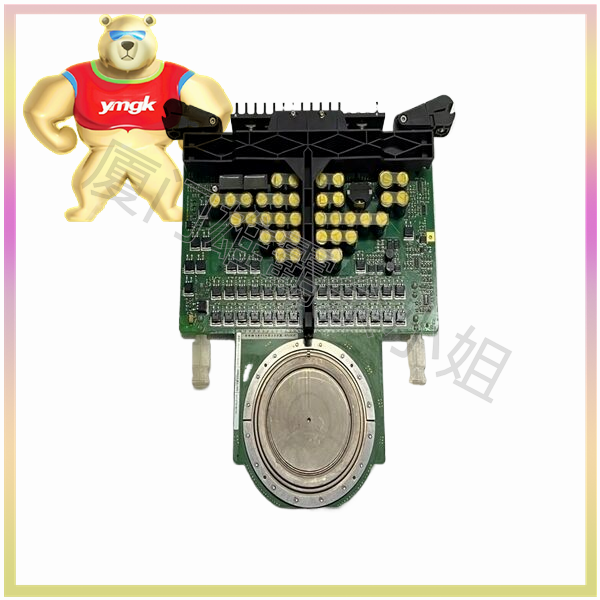

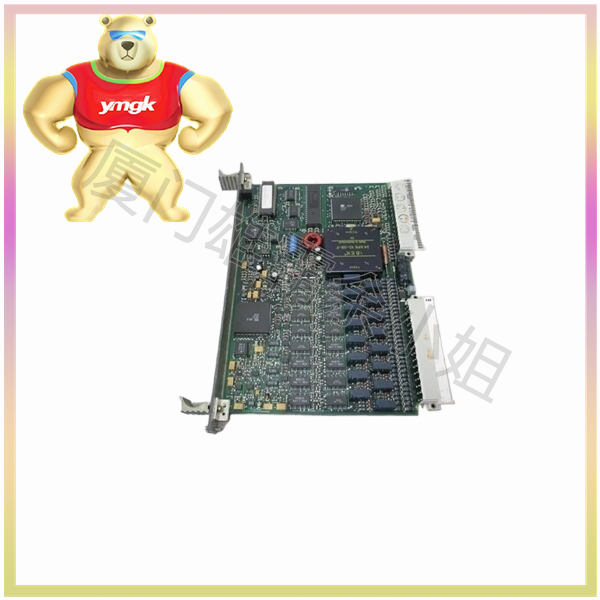

- Electric drive: The electric drive converts electrical energy into mechanical energy through an electric motor to achieve the operation of mechanical equipment. The working principle of electric motors mainly includes DC motors, AC motors, stepper motors, servo motors, etc.

- Hydraulic Drive: Hydraulic drives convert hydraulic pressure energy into mechanical energy through hydraulic pumps, enabling the operation of mechanical equipment. The working principle of hydraulic actuators includes the collaborative work of components such as hydraulic pumps, hydraulic cylinders, and hydraulic valves.

- Pneumatic actuator: Pneumatic actuators convert gas pressure energy into mechanical energy through pneumatic components to achieve the operation of mechanical equipment. The working principle of pneumatic actuators includes the coordinated operation of components such as pneumatic cylinders, pneumatic valves, and air sources.

4、 The application of drivers in different fields

- Industrial automation field: Drivers play an important role in the field of industrial automation, such as robots, automated production lines, conveyor belts, and other equipment that require drivers to achieve precise control and efficient operation.

- Transportation field: Drivers are also widely used in the transportation field, such as electric vehicles, rail transit, ship propulsion, etc., all of which require drivers to provide power and achieve control.

- Construction field: The application of drivers in the construction field includes elevators, automatic doors, sunshade systems, etc., all of which require drivers to achieve precise control and safe operation.

- Medical equipment field: The application of drivers in medical equipment includes surgical robots, rehabilitation equipment, diagnostic equipment, etc., all of which require drivers to achieve precise control and efficient operation.

- In the field of agricultural machinery: The application of drivers in agricultural machinery includes harvesters, seeders, tractors, etc., all of which require drivers to provide power and control.

5、 The development trend of drivers

- High performance: With the development of technology, the performance of drives continues to improve, such as high efficiency, high precision, and high reliability.

- Intelligence: The intelligence level of the drive is constantly improving, such as self diagnosis, adaptive control, remote monitoring and other functions.

- Integration: The integration level of drivers continues to improve, integrating multiple functions into one driver to achieve integrated control.

- Greening: The green development of drivers is receiving increasing attention, such as energy conservation, environmental protection, low noise, etc.

- Customization: According to the needs of different industries and application scenarios, customized design of drivers is increasingly being valued.

Summary: Drivers play a crucial role in modern mechanical equipment and systems, with a wide variety of types and diverse functions. With the development of technology, the performance, intelligence level, integration degree and other aspects of drives continue to improve, providing strong support for the development of various industries. In the future, drivers will continue to develop towards high-performance, intelligent, integrated, green, and customized directions, making greater contributions to the progress of human society.