In today’s era, industrial automation control has a wide range of applications, and remote I/O modules are an indispensable part of it. More and more scenarios require remote data acquisition and transmission in industrial automation, among which dual network port cascaded remote I/O modules have become one of the commonly used devices in the industry. This article will discuss the application scenarios and characteristics of dual network port cascaded remote I/O modules from the perspective of industrial automation.

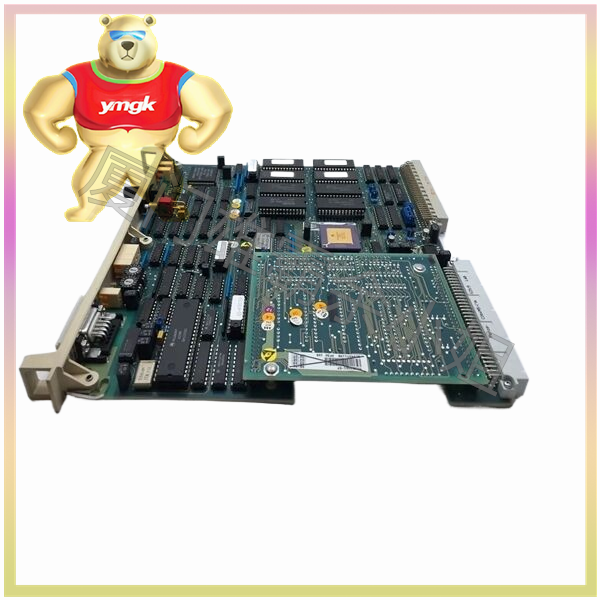

Firstly, we need to understand what a remote I/O module is. Simply put, it is a device that collects and converts external signals (such as temperature, pressure, flow rate, etc.), and remotely transmits these signals to control systems (such as PLC, DCS, etc.) through the network. In industrial production, these signals are usually related to the automation of factory production. Taking automobile production as an example, temperature, humidity, pressure and other parameters are factors that need to be closely monitored during the process of body spraying, baking paint and other processes. However, automobile assembly lines are usually several hundred meters long. If local I/O is used, a large number of wiring will be generated on site, which not only causes the workshop circuit to be congested and complex, but also leads to signal and voltage attenuation. This has caused inconvenience for later maintenance and system expansion, increasing the cost of equipment installation, debugging, and maintenance. So using remote I/O modules can not only help factories monitor these parameters, but also reduce the cost of long-distance wiring, and solve the problem of many easily broken cables in some workshops, achieving production process automation and quality control.

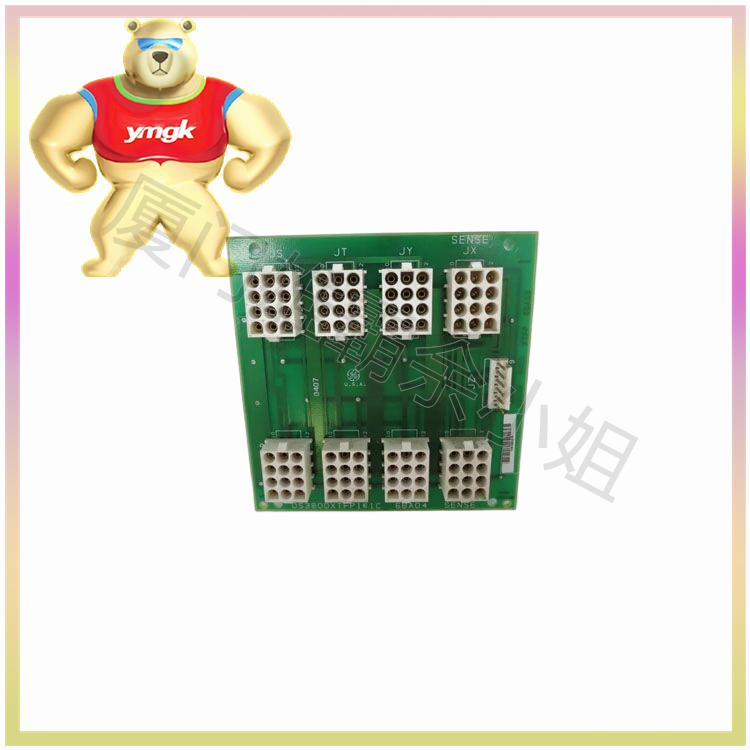

Dual port cascading is an important advantage of dual port cascading remote I/O modules. It supports cascading multiple I/O modules to support more I/O points. In industrial sites, there are often a large number of signals that need to be collected, but the number of ports that a single I/O module can provide is limited. Through cascading, we can connect multiple I/O modules to form a scalable daisy chain Ethernet remote I/O array, which can flow freely downwards to another local Ethernet device or upwards to the server. This allows us to cope with situations where we were unable to meet the demand. The daisy chain function of remote I/O modules not only improves the scalability and installation possibilities of remote I/O applications, but also reduces the need for separate Ethernet switches, lowers overall costs, and reduces overall labor and wiring costs.

In summary, the dual network port cascaded remote I/O module is a commonly used type of PLC remote I/O extension in industrial automation. Its advantages lie in achieving dual protection, increasing the number of I/O extensions, and reducing wiring costs. It is suitable for scenarios that require multiple and scattered data points to be collected. This product significantly reduces the customer’s cost input and has a clear price advantage compared to imported brands.

Typical applications

01 Collaborative Robot Control

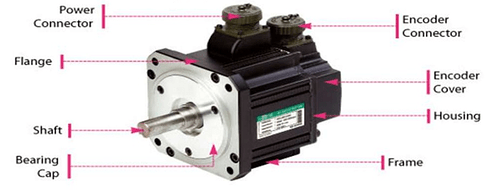

The MxxxE remote I/O module can transmit various sensor signals to the collaborative robot CPU for processing, and then control each execution system through corresponding I/O interfaces, bringing a series of convenient services to the robotics industry. At the same time, the compact size and installation method of MXXT modules solve the problem of tight wiring for customers on site.

Collaborative robots

02 Semiconductor production

In semiconductor production and manufacturing, there are often many valve islands, drivers, sensors, and pneumatic or electrical control equipment. The MxxE remote I/O module can achieve the acquisition and control of corresponding signals.

03 Photovoltaic and Wind Power

The photovoltaic industry is a sunrise industry that has emerged based on the demand for new energy, and it is also a future industry strongly supported by the country for development. The MxxE remote I/O module can collect data from photovoltaic inverter controllers, various sensors, control terminals, and other related devices to upload data and issue instructions to the photovoltaic control system.

04 3C lithium battery production

In the production of 3C lithium batteries, a large generation line requires high precision and high uniformity, so strict control is needed on key parameters such as pressure, time, and temperature. The MxxE remote I/O module needs to collect these parameters, transmit control instructions, and achieve fast, accurate, and reliable performance in key links.

05 Port Terminal

During the process of container handling, various practical obstacles may be encountered. In grasping, moving, and placing containers, it is necessary to demonstrate their ability to transport stably. The MxxE remote I/O module transmits various switch signals and photoelectric detection signals to the PLC to assist in completing various refined operations with stable performance.