The role of IO module

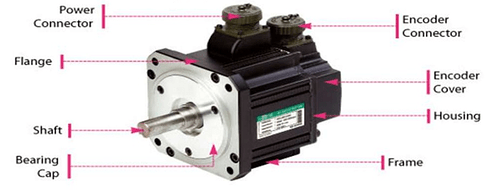

Data collection and transmission: In industrial production, IO modules are responsible for collecting data from various sensors and detection devices, such as temperature, pressure, humidity, etc., and transmitting these data to the central processing unit (CPU) or programmable logic controller (PLC) for processing. At the same time, it is also responsible for transmitting processed instructions to actuators such as motors, valves, etc. to control the production process.

Signal conversion: Equipment used in industrial production often involves multiple types of signals, such as analog signals and digital signals. The IO module can achieve the conversion between these signals, ensuring compatibility between different devices and accuracy of data transmission.

Device control: IO modules can directly control on-site devices, such as starting or stopping motors, opening or closing valves, etc. It can achieve precise control of the production process based on instructions from the central control system.

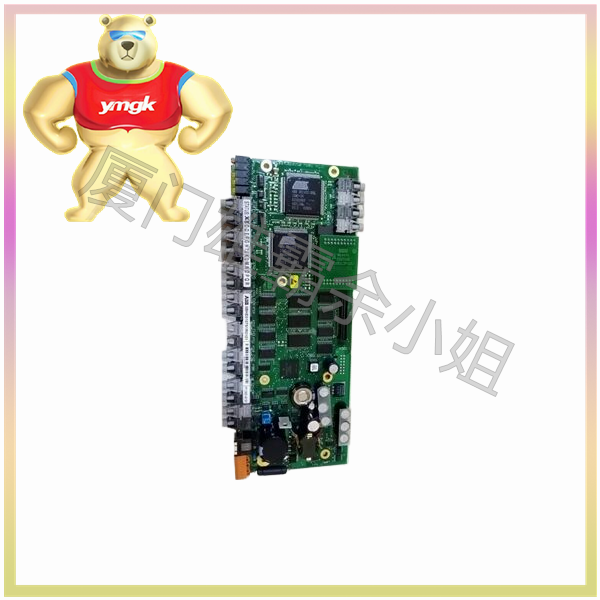

Fault diagnosis and safety monitoring: IO modules can monitor the real-time operation status of equipment and issue timely alarms when abnormalities are detected. This helps to detect problems in a timely manner, prevent equipment damage and production accidents.

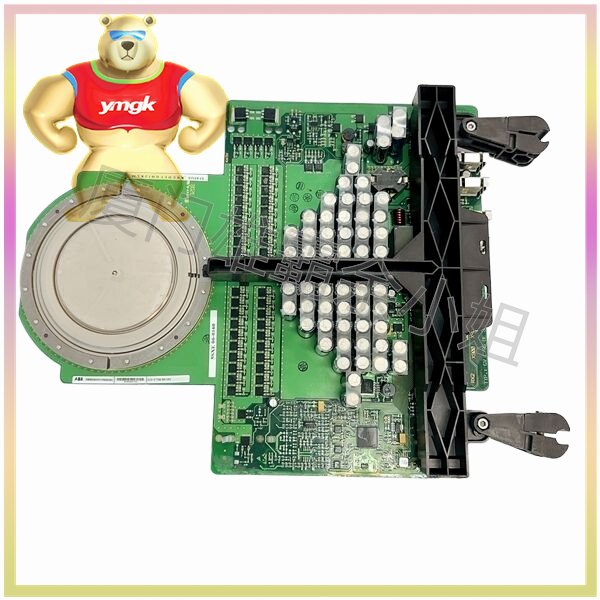

The Importance of IO Modules in Industrial Production

Improve production efficiency: Through precise data collection and equipment control, IO modules can optimize production processes, reduce manual intervention, and improve production efficiency.

Ensuring product quality: IO modules can ensure the stability and consistency of the production process, thereby ensuring product quality.

Enhance system stability: The design of IO modules usually considers the harsh conditions of industrial environments, such as high temperature, high pressure, electromagnetic interference, etc., so they have strong stability and reliability.

Reduce maintenance costs: The fault diagnosis function of IO modules can help operators quickly locate problems, reduce maintenance time and costs.

Enhance system flexibility: With changes in production requirements, IO modules can be easily expanded and replaced, making industrial control systems more flexible and scalable.

With the advancement of Industry 4.0, IO modules will continue to play an important role in intelligent and networked industrial production.